Shunzhi Vertical Shaft Impact Crusher

Shunzhi vertical shaft impact crusher (VSI) improves working efficiency to around 56% and meanwhile give excellent cubic particle shape to help reduce 25% unnecessary costs for your whole project.

Our machine is a high-energy and low consumption device that can be used to reduce ore fines into gravel. This type of machine has been proven as one with great efficiency in various other crushing equipment, making it an irreplaceable part for anyone seeking quality materials from their raw stock!

VSI Crushers For Sale

High performance Shunzhi vsi crusher – Vertical Shaft Impact Crusher & Mobile VSI Crusher Plants In Large Stock!

Feeding Size: 0-60mm

*Note: Can Be Customized.

Capacity: 60-750t/h

*Note: Can Be Customized.

Applicable Materials:

Suitable for crushing cobblestone, basalt, granite, iron ore, copper ore, cement, artificial sand, fluorite, limestone.

Applicable Fields:

Widely used in Aggregate shaping, machine-made sand, building materials, mining, chemical industry, metallurgy, road construction, water conservancy and other industries.

Types of Vertical Shaft Impact Crushers for Sale

Vertical shaft impact crushers, or vsi crusher, are a type of crusher that uses high speed rotor to impeller technology to create an intensive collision force. This versatile piece of equipment can be used in many industries for a variety of applications.

However, there are three main types of VSI crushers for sale in Shunzhi: vertical shaft impact crusher, VSI mobile crushing station and VSI crawler mobile crushing station. Here is a brief overview of each type to help you choose which one is right for your business.

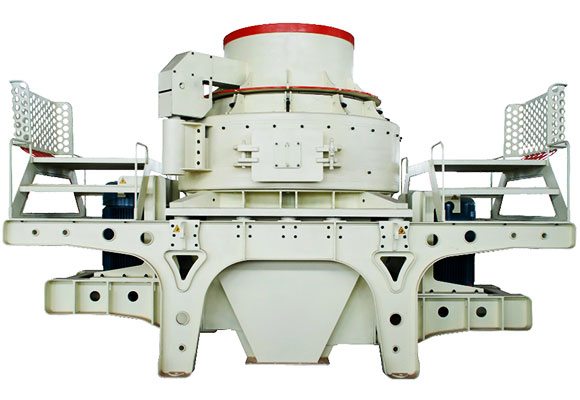

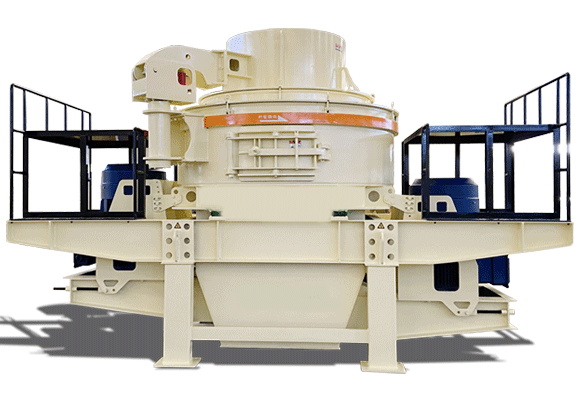

(VSI) Vertical Shaft Impact Crusher

The vertical shaft impact crusher is a type of sand making machine that widely used in the process of manufacturing highway, expressway, gravel, and concrete mixing station.

It is suitable for crushing medium or above hardness materials such as iron ore, nonferrous metal ore, corundum, bauxite, quartz sand, brown aluminum oxide, perlite, Basalt, etc.

| Model | VSI5X7615 ~ VSI5X1145 |

| Throughput capacity (t/h) | 150~280, 500~640 |

| Overall Dimension L×W×H (mm) | 4100×2330×2300, 5000×2790×3320 |

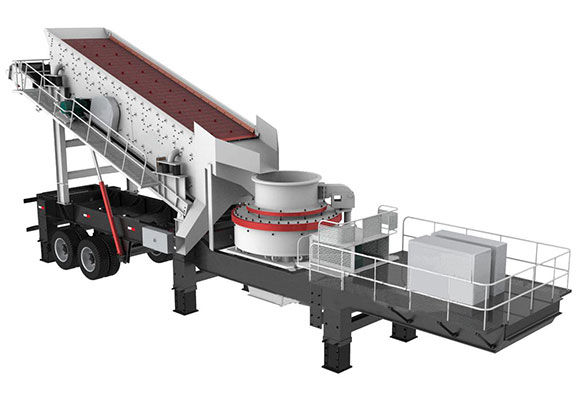

VSI Mobile Crushing Station

The VSI mobile crushing station is a fully equipped crushing unit that uses vertical shaft impact (VSI) crushers to produce high quality aggregates and sub-base materials.

This mobile crushing station can be easily transported on-site and provides flexibility in terms of location and layout.

The VSI crushers used in this mobile crushing station have been shown to be very effective in producing high quality aggregates and sub-base materials.

| Model | SZYY300 ~ SZYY750 |

| Overall Power (kw) | 268.5 ~ 441 |

| Capacity(t/h) | 120-320 ~ 180-284 |

Differences Between VSI and Other Vertical/Horizontal Impact Crushers

When comparing Vertical Shaft Impact (VSI) crushers with other impact crushers, such as Horizontal Shaft Impact (HSI) crushers, several key differences emerge.

Design and Operation: VSI crushers utilize a high-speed rotor that propels particles into a crushing chamber, where they collide with other particles or anvil surfaces for size reduction. In contrast, HSI crushers have hammers fixed to a rotating shaft, which strike materials as they enter the crushing chamber, creating a more direct, impact-driven reduction.

Product Shape: VSI crushers are known for producing highly cubical-shaped aggregates due to their unique crushing process, making them ideal for applications where particle shape is crucial. HSI crushers, while effective, typically yield more elongated shapes.

Strengths:

- VSI Crushers: Superior granulation, reduced wear on components, and high throughput in scenarios requiring fine product sizes.

- HSI Crushers: Higher capacities and better suited for softer materials; they often offer greater flexibility in material size reduction.

Weaknesses:

- VSI Crushers: Generally more prone to wear and tear due to the high-speed impacts and may be less effective with harder, more abrasive materials.

- HSI Crushers: Limited in producing high-quality fine aggregates and producing more elongated shapes, which may not meet specific quality requirements.

Overall, the choice between VSI and other impact crushers depends on the application, desired product characteristics, and the material being processed.

Shunzhi Vertical Shaft Impact (VSI) Crusher Price List

| Types | Price Range |

| Vertical Shaft Impact Crusher | $14,000 – $70,000 |

| VSI Mobile Crushing Station | $30,000 – $150,000 |

| VSI Crawler Mobile Crushing Station | $30,000 – $150,000 |

Vertical Shaft Impact crusher prices are mainly determined by the type and size of your project.

The more you know about these machines, as well as other factors such cost or delivery requirements for example; then we can help make sure that any decision regarding which one will work best with those qualities in mind!

Cost of Ownership and ROI Analysis of VSI Crushers

When considering the cost of ownership for a Vertical Shaft Impact (VSI) crusher, several factors come into play that influence the overall return on investment (ROI). The initial investment includes the purchase price, installation costs, and the necessary infrastructure to support operation. While VSI crushers may have a higher upfront cost compared to other types of crushers, their long-term benefits often justify the expense.

VSI crushers are designed for durability and longevity, typically exhibiting lower wear rates and maintenance requirements. This reliability translates to reduced operational downtime and lower maintenance costs over the equipment’s lifecycle. Additionally, their ability to produce high-quality, cubical-shaped aggregates enhances the end product’s market value, leading to higher selling prices.

In terms of productivity, VSI crushers offer efficient processing capabilities that can yield high output levels, maximizing throughput while minimizing operating costs. The versatility of these crushers allows for processing a variety of materials, including recycled content, which can further enhance profitability.

When analyzing ROI, it’s essential to consider not just the initial investment but also potential savings in maintenance, increased production capacity, and the ability to deliver superior products that meet high market demand. Ultimately, the strategic use of VSI crushers can result in a favorable cost-benefit scenario for operators in the aggregate industry.

Our Advantages

Shunzhi vertical shaft impact crusher is a high-efficiency environmentally friendly crushing equipment independently developed by our company. Welcome customers from all over the world to visit our factory for further consultation!

Our vertical shaft impact crusher is designed with brilliant quality level, to ensure uniform cubic particle size, and the content of needle and flake is extremely low, thus is suitable for aggregate shaping.

97%

UNIFORM PARTICLE SIZE

Fine crushing and coarse grinding functions on our VSI crusher improve working efficiency to around 56%, and the simple structure also reduces a large amount of operating costs.

+56%

WORKING EFFICIENCY

The machine has strong ability to pass through non broken materials, and is less affected by the moisture content of materials, meaning it can be used in multiple mining and highway construction use.

79%

APPLICATIONS

With advanced technology as well as robust parts used in machine, we reduce 30% iron pollution and meanwhile gives bulk density of products, so that it can reduce 25% unnecessary costs.

-30%

IRON POLLUTION

Role of VSI Crushers in Sustainable Practices

Vertical Shaft Impact (VSI) crushers play a significant role in promoting sustainable practices in the aggregate and construction industries. One of their key contributions to environmental sustainability is through enhanced recycling efficiencies. VSI crushers are highly effective in processing recycled materials, such as concrete and asphalt, allowing for the repurposing of waste into usable aggregates. This not only reduces the demand for virgin materials but also minimizes landfill accumulation, contributing to a circular economy.

Moreover, the design of VSI crushers allows for energy-efficient operation. They generally require less energy than traditional crushing methods, leading to lower greenhouse gas emissions during the production of aggregates. By optimizing the crushing process to produce high-quality outputs with minimal energy consumption, VSI technology supports both environmental and economic sustainability.

Additionally, the ability of VSI crushers to produce cubical particles improves the performance of concrete and asphalt mixtures, thereby extending the lifespan of infrastructure and reducing the frequency of repairs or replacements. Ultimately, employing VSI crushers aligns with sustainable development goals by minimizing environmental impact, promoting efficient resource use, and supporting recycling initiatives, which are vital for reducing the carbon footprint of construction activities.

How Shunzhi Vertical Shaft Impact (VSI) Crusher Improves Your Business?

Robust and Reliable Design

Designed with a welded carbon steel frame and chrome iron feed plate, impeller shoes and external feed pipe, Shunzhi vertical shaft impact crusher is highly robust and reliable in working.

Flexible and Adjustable

Multiple models in mobile vertical shaft impact crushers allow you to use it in any applications thanks to its super flexiblity performance, and you can also adjust its configuration based on your needs.

Wide Rotor Speed Range

Ranging from 1700~1900r/min rotation speed to 1100~1310r/min speed, our machine provides precise control over product quality and gradation.

Large production capacity

The maximum center and ring feeding throughput capacity reaches 500~640t/h, while the center feeding throughput capacity goes up to 250~360t/h, enabling our machine to be widely used in multiple applications.

Working Principle of Vertical Shaft Impact Crusher

The working principle of a Vertical Shaft Impact (VSI) crusher revolves around the accelerated particles impacting against a material, usually rock, to achieve the desired size reduction and shaping. The core mechanism of a VSI crusher involves a high-speed rotor, which spins at high revolutions per minute (RPM).

Initially, the material is fed into the center of the rotor, where it is rapidly thrown outward by centrifugal force. As the particles leave the rotor, they impact against fixed anvils or other rock particles in the crushing chamber. This impact creates a high degree of fragmentation and shapes the material into cubical products, which is particularly beneficial in the production of high-quality aggregates.

The unique design of a VSI crusher allows for the control of product shape and size, making it versatile for various applications including sand making, and shaping of stone in gravel quarries. Additionally, the closed-circuit design often employed in VSI operations allows for the efficient recycling of material, thereby maximizing the use of resources. The ability to operate with low wear rates and reduced energy consumption further enhances the appeal of VSI technology in aggregate processing and other material production industries.

Global Cases

VSI5X9532 VSI Crusher Works in the South Africa

Congratulations! Our VSI5X9532 VSI crusher helped our customers finished a large mining project lately and their high working performance are once again proved.

VSI5X1145 VSI Crusher Sent to Kenya

Another set of VSI5X1145 VSI crusher was sent to Kenya and began working for few months, according to feedback, they are in excellent working conditions now.

VSI5X7615 VSI Crusher Sent to Nigeria

The center and ring feeding of this VSI5X7615 VSI crusher is 150-280t/h, after sending to Nigeria, this machine has played important role in stone crushing till now.

SZCLY800 VSI Mobile Crushing Station Works in Philippines

We are so glad our VSI mobile crushing station work perfectly in Philippines, the customers praise that our machine are highly flexible and reduce much operating costs for them.

Specifications

| Model | VSI5X7615 | VSI5X8522 | VSI5X9532 | VSI5X1145 |

| Center and Ring feeding Throughput capacity (t/h) | 150~280 | 240~380 | 350~540 | 500~640 |

| Center feeding Throughput capacity (t/h) | 70~140 | 120~190 | 180~280 | 250~360 |

| Soft material Max. Feed Size (mm) | <35 | <40 | <45 | <50 |

| Hard material Max. Feed Size (mm) | <30 | <35 | <40 | <45 |

| Rotation speed (r/min) | 1700~1900 | 1500~1700 | 1300~1510 | 1100~1310 |

| Power of double motor (KW) | 2×75 (100) | 2×110 (150) | 2×160 (220) | 2×220 (300) |

| Overall dimension L×W×H (mm) | 4100×2330×2300 | 4140×2500×2700 | 4560×2600×2900 | 5000×2790×3320 |

| Weight (t) | 8.6 | 11.8 | 17.5 | 27.5 |

| Power for double oil pump | 2×0.25(0.33) | 2×0.25(0.33) | 2×0.25(0.33) | 2×0.25(0.33) |

| Power for oil box heater | 2 KW | 2 KW | 2 KW | 2 KW |

| Overall dimension L×W×H (mm) | 820×520×1270 | 820×520×1270 | 820×520×1270 | 820×520×1270 |

What Do Customers Talk About Us?

If you ordered machine from Shunzhi, you will know my feelings now. We orded the vsi machine from them 2 years ago and so glad that I have already get my investment back.

– Trey Yosef Manlapaz Panopio

The vertical shaft impact crusher we ordered are in perfect working performance, they really work as advertised, would cooperate with them again!

– Tito David Talatala Samonte

Frequently Asked Questions

Featured Products

Shunzhi Hammer Crusher

Shunzhi hammer crusher is suitable for crushing hard and medium hard materials in many industrial departments such as cement, chemistry, power station and metallurgy. The working principle is…