Shunzhi Auxiliary Machine

Premium quality level of our machines bring optimal working performance, reduce 35% costs of your projects.

During the whole crushing process, all our auxiliary machines play vital roles. From vibrating feeder, belt conveyor, vibrating screen to sand washer and fine sand reclaimer, you’ll get what you want from Shunzhi.

Types of Auxiliary Machines for Sale

Apart from the major crushing machines working in the primary and secondary crushing, such as jaw crusher, cone crusher, hammer crusher, and VSI crusher, the auxiliary machines also play an important role in the whole project.

There are six main types of auxiliary machines in Shunzhi for sale, including vibrating feeders, belt conveyors, vibrating screens, wheel-type sand washers, spiral sand washers, and fine sand reclaimers. Built with robust materials and advanced technology, all our auxiliary machines are of brilliant quality. Contact us to get your customized solutions now!

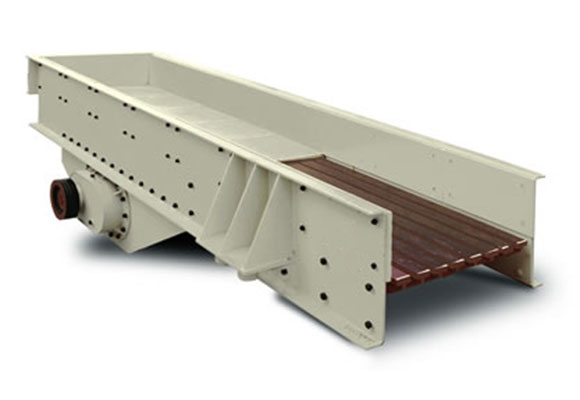

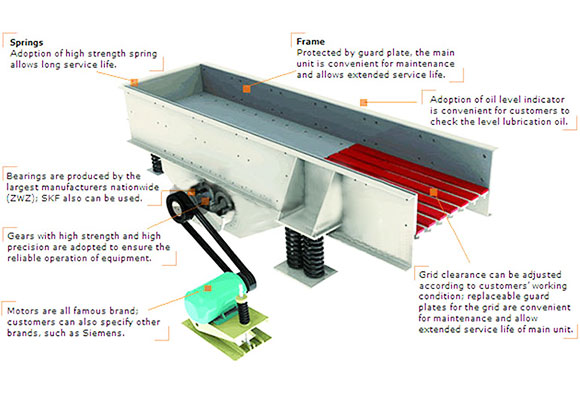

Vibrating Feeder

Shunzhi vibrating feeder is the simplest and most economical way to transfer material in large quantities.

Its main function is to meter the flow of bulk materials to secondary processes or final discharge.

Our vibrating feeders offer a number of advantages over other methods of conveying material. They are faster, more versatile, and can handle large volumes of material with ease and can be used in a variety of industries.

| Model | GZD750×2500 ~ GZD1500×6000 |

| Capacity(t/h) | 50-80 ~ 500-850 |

| Max Feeding Size(mm) | 300 ~ 950 |

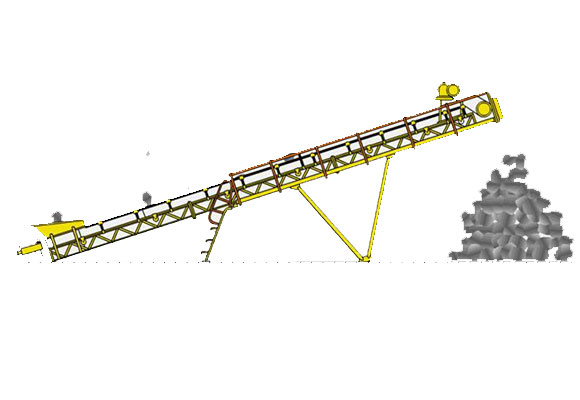

Belt Conveyor

Belt conveyors are an integral part of any stone crushing operation. They provide the means by which raw materials are transported from one stage of the crushing process to the next, and ultimately to the storage area for finished products.

Belt conveyors are available in a variety of sizes and configurations, and can be customized to meet the specific needs of your stone crushing operation.

| Tape Width(mm) | 400 ~ 2400 |

| Conveying Speed(m/s) | 1.25-2.0 ~ 1.0-2.0 |

| Conveying Capacity(t/h) | 30-60 ~ 1500-3000 |

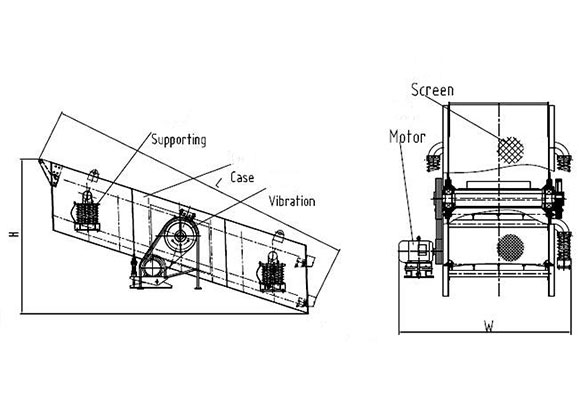

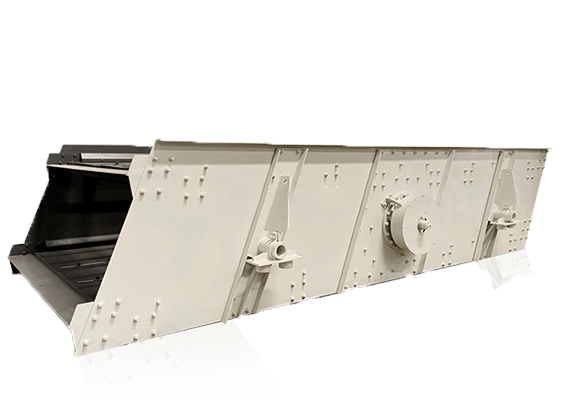

Vibrating Screen

Vibrating screens are critical machines used for size classification in mineral processing.

Their proper operation, including attend to the feed material characteristics, capacity and terms of the desired final products, can provide efficient and cost-effective stone crushing operations.

| Model | JC231 ~ JC983 |

| Size of Feed Opening(mm) | 510×800 ~ 1800×2100 |

| Capacity(t/h) | 50-250 ~ 700-2100 |

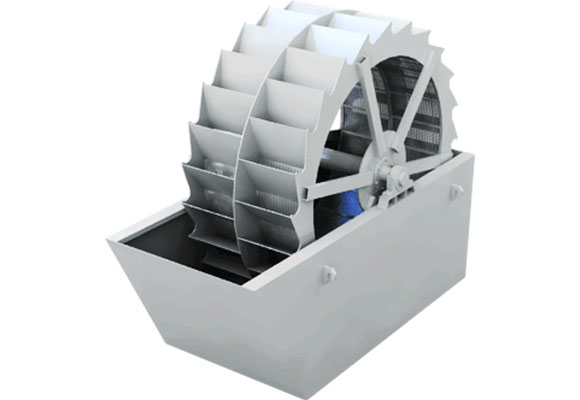

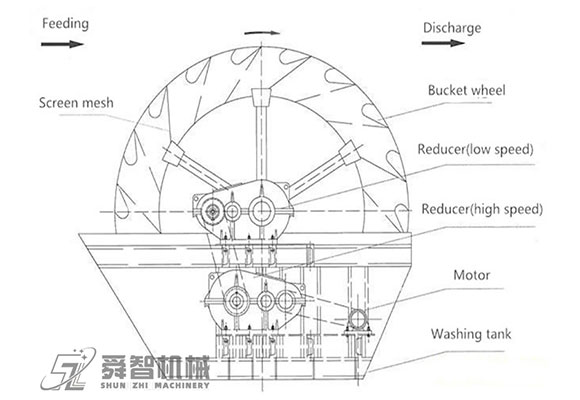

Wheel Type Sand Washer

A wheel type sand washer is a key piece of equipment used in stone crushing. It is generally used to cleanse raw materials or remove impurities from finished products.

The washer works by agitating the material in a washing solution, typically water with detergent, to loosen and remove contaminants.

Wheel type sand washers are available in a variety of sizes and configurations to meet the needs of different applications. From 20t/h to 200t/h, you can customize your machine based on your needs from Shunzhi.

| Model | XSD1808 ~ XSD3624 |

| Impeller Size(mm) | 1800×800 ~ 3600×2400 |

| Capacity(t/h) | 20-40 ~ 120-200 |

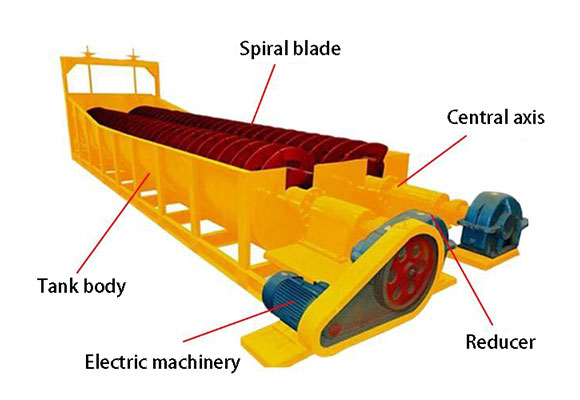

Spiral Sand Washer

A spiral sand washer is a type of sand washing machine that is frequently used in the processing of loose materials.

In terms of operation, the spiral sand washer rotates slowly, whenever stone crushing is taking place.

At the same time, the water will enter into the spiral bucket in order to remove any impurities that are present on the surface of the crushed stones.

| Model | LX0920 ~ 2LX1500 |

| Spiral Diameter(mm) | 920-1500×2 |

| Capacity(t/h) | 30-60 ~ 120-250 |

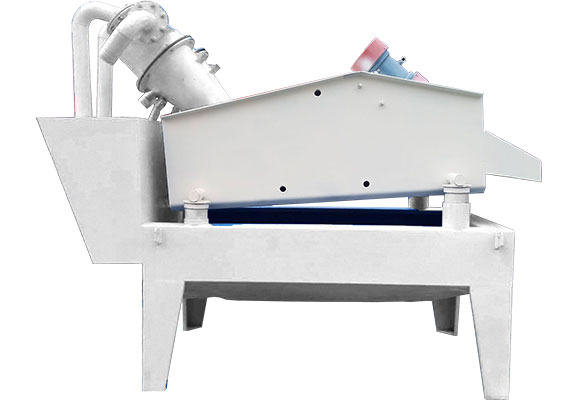

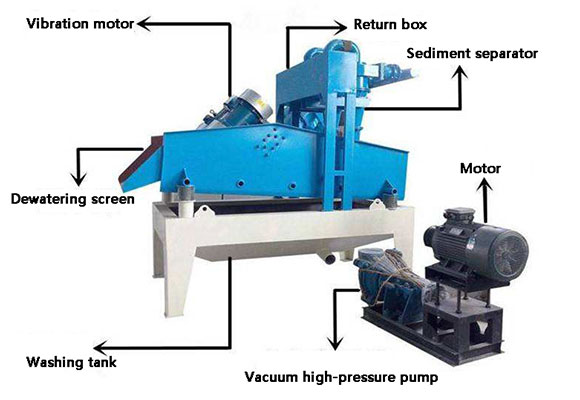

Fine Sand Reclaimer

Fine sand reclaimers sift through and collect the fines generated during the crushing process so they can be reintroduced into the system.

The reclamation process not only saves money but also prevents the waste of a valuable resource. In many cases, the sand that is collected is of better quality than what is naturally occurring in the environment.

| Model | SZ8018 ~ 2SZ2060 |

| Capacity(tph) | 5-10 ~ 200-260 |

| Separator Specification | 250 ~ 500×2 |

Our Advantages

Shunzhi auxiliary machines include various types and models, for all working conditions, you can get what you need from Shunzhi. Call us anytime if you have interest and we will give rapid feedback and solutions based on your needs.

From vibrating screen to belt conveyor, all our mining equipment rarely have wearing parts, and all are equipped with anti-worn parts to reduce your maintenance costs by at least 40%.

-40%

MAINTENANCE COSTS

Advanced technology with simple structure design make our equipment highly efficient in working, according to test, the performance of our machine is 86% higher than others.

86%

WORK PERFORMANCE

Auxiliary machines are not only available for stone crushing in mining, you can also use in various industries, which means you can get your investment back in years or even months.

95%

APPLICATIONS

Large amount of costs may be wasted in many mining projects, but with our machines, you’ll find that operation costs is significantly reduced to at least 30%, for operating them are super easy.

-30%

operation costs

Shunzhi Jaw Crusher Price List

| Types | Price Range |

| Vibrating Feeder | $1,300 – $10,000 |

| Belt Conveyor | $500 – $6,000 |

| Vibrating Screen | $2,700 – $25,000 |

| Wheel Type Sand Washer | $4,000 – $15,000 |

| Spiral Sand Washer | $4,000 – $20,000 |

| Fine Sand Reclaimer | $3,000 – $15,000 |

The auxiliary machines are key parts in the stone and mining crushing process, the price range above is just a reference price range, the detailed price and cost are determined by product capacity and model, but for each machine, we offer customized service based on your needs.

Apart from the premium-quality products offered, we will also give you tailor-made solutions for your projects, contact us anytime if you have any interest or problem with our products.

Global Cases

Vibrating Feeder Works in the Philippines

Another set of vibrating feeder was sent to Philippines and started its work last month, the model is GZD1100x4200, which has 180-400t/h capacity, meets the customers’ needs of 300t/h.

Belt Conveyor Sent to South Africa

After getting the customers’ quotation, we offered customized solutions for this customer from South Africa, and he is glad that our belt conveyor works perfectly with his production line.

Vibrating Screen Sent to Kenya

Congratulations! Another set of vibrating screen was sent to Kenya, we sent our engineers for installation and machine tests, and proved that our machine is in optimal conditions.

Wheel Type Sand Washer Works in Pakistan

The wheel type sand washer was sent to Pakistan in just a few days, it soon worked in local large projects.

Features of Shunzhi Vibrating Feeder

Reliable and stable design

All the internal parts, especially vibrators, are delicately designed to ensure highly reliable and stability in use so that the materials can be smoothly transported to the next stage.

Anti-block in transporting

The adjustable special grid bar design prevents any material blockage in transporting process.

Wear-resistant parts

Our machine also includes safety designs to prevent worn parts from being worn by small materials, separate small materials, and increase output.

Variable frequency adjustable speed motor

The variable frequency motor can be installed to adjust the output, so that you may change how much material is being fed at any given time. It also takes care of regulates and eliminates wasted produce by only feeding it when necessary!

Specifications of Vibrating Feeder

| Model | Feeding Chute Size(mm) | Max Feeding Size(mm) | Capacity(t/h) | Motor Power(kw) | Weight(kg) | Overall Dimension(mm) |

| GZD750x2500 | 750×2500 | 300 | 50-80 | 3 | 1590 | 2580x1100x1400 |

| GZD850x3000 | 850×3000 | 400 | 80-120 | 7.5 | 3895 | 3110x1800x1600 |

| GZD960x3800 | 960×3800 | 500 | 120-210 | 11 | 4210 | 3850x1950x1630 |

| GZD1100x4200 | 1100×4200 | 650 | 180-400 | 15 | 4850 | 4400x2050x1660 |

| GZD1100x4900 | 1100×4900 | 650 | 220-460 | 15 | 5500 | 5200x2050x1700 |

| GZD1300x4900 | 1300×4900 | 800 | 300-550 | 22 | 6680 | 5200x2350x1750 |

| GZD1500x6000 | 1500×6000 | 950 | 500-850 | 30 | 9970 | 6160x2918x2292 |

Features of Shunzhi Belt Conveyor

Large conveying capacity

The conveying capacity range from 30 to 3000t/h, allowing you to use it for small and large projects.

Tailor-made based on needs

The conveyor system can be a single piece or composed of multiple units. Or you could combine them with other equipment to form an inclined or horizontal line for different layouts in need!

Large temperature range

With the ability to operate at low and high temperatures, this conveyor belt is perfect for any industry. It can be used in a wide range of conditions from – 20 ℃ all way up past +40 degrees Celsius without breaking down or wearing out!

Easy to match with other products

Shunzhi belt conveyer occupies a small floor area, making it more convenient to match with the production line.

Specifications of Belt Conveyor

| Tape width (mm) | Conveying length (m) | Conveying length (m) | Conveying length (m) | Conveying speed (m/s) | Conveying capacity (t/h) |

| Tape width (mm) | Power (kw) | Power (kw) | Power (kw) | Conveying speed (m/s) | Conveying capacity (t/h) |

| 400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 400 | 3 | 3-4 | 4-7.5 | 1.25-2.0 | 30-60 |

| 500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 500 | 3 | 4-5.5 | 5.5-7.5 | 1.25-2.0 | 40-80 |

| 650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 650 | 4 | 7.5 | 7.5-11 | 1.25-2.0 | 80-120 |

| 800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 800 | 4 | 7.5 | 7.5-15 | 1.25-2.0 | 120-200 |

| 1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 1000 | 5.5 | 7.5-11 | 11-22 | 1.25-2.0 | 200-320 |

| 1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 1200 | 7.5 | 7.5-15 | 15-30 | 1.25-2.0 | 290-480 |

| 1400 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 400-680 |

| 1400 | 11 | 15-22 | 22-45 | 1.25-2.0 | 400-680 |

| 1600 | ≤10 | 10-20 | 20-50 | 1.25-2.0 | 600-1080 |

| 1600 | 15 | 22-30 | 30-75 | 1.25-2.0 | 600-1080 |

| 1800 | ≤10 | 10-20 | 20-50 | 1.0-2.0 | 800-1500 |

| 1800 | 18.5 | 30-45 | 45-110 | 1.0-2.0 | 800-1500 |

| 2000 | ≤10 | 10-20 | 20-50 | 1.0-2.0 | 1000-2000 |

| 2000 | 22 | 45-55 | 55-132 | 1.0-2.0 | 1000-2000 |

| 2400 | ≤10 | 10-20 | 20-50 | 1.0-2.0 | 1500-3000 |

| 2400 | 30 | 55-75 | 75-185 | 1.0-2.0 | 1500-3000 |

Features of Shunzhi Vibrating Screen

High efficiency with large capacity

Shunzhi vibrating screen has high screen frequency, small amplitude, and high working efficiency, its capacity range from 50 to 2100t/h.

Easy-to-maintain design

The circular vibrating screen uses an eccentric shaft and block to adjust its amplitude. This is easy for users, since it requires minimal maintenance work on their part!

Long service life and low noise

By using spring steel woven screen mesh or perforated screen plate, our machine owns longer service life and lower noise in working.

Wide range of application

The vibrating screen can be widely used for product classification in mining, building materials, transportation, energy, chemical and other industries.

Specifications of Vibrating Screen

| Model | Size of Feed Opening(mm) | Discharge Range(mm) | Capacity(t/h) | Motor Power(kw) | Weight (Excluding Motor)(kg) |

| JC231 | 510×800 | 40-150 | 50-250 | 55-75 | 9052 |

| JC340 | 600×1020 | 60-175 | 85-300 | 75-90 | 16460 |

| JC3540 | 650×1060 | 110-225 | 120-400 | 75-90 | 16872 |

| JC440 | 760×1020 | 70-200 | 120-520 | 90-110 | 27810 |

| JC443 | 850×1100 | 80-215 | 170-625 | 110-160 | 34722 |

| JC549 | 950×1250 | 110-250 | 260-810 | 132-160 | 50308 |

| JC5149 | 1100×1250 | 160-300 | 350-900 | 132-160 | 50550 |

| JC555 | 1070×1400 | 125-250 | 360-920 | 160-200 | 58907 |

| JC5155 | 1170×1400 | 225-350 | 600-1100 | 160-200 | 60162 |

| JC649 | 1100×1250 | 125-280 | 385-920 | 160-200 | 55954 |

| JC659 | 1200×1500 | 150-350 | 400-1200 | 200-250 | 90089 |

| JC663 | 1200×1600 | 150-350 | 500-1450 | 220-250 | 90789 |

| JC771 | 1500×1800 | 150-350 | 600-1800 | 315-400 | 124413 |

| JC983 | 1800×2100 | 175-350 | 700-2100 | 355-450 | 180000 |

Features of Shunzhi Wheel Type Sand Washer

Simple structure

Its simple structure design reduces the unnecessary costs in operating, from 20-200t/h capacity, and the machine works in perfect working conditions.

Long service life

The machine has almost no wearing parts except the screen, which means it has a longer service life.

Wide range of application

The wheel bucket-type sand washer is widely applicable to the washing, grading, impurity removal, and other operations in metallurgy, building materials, hydropower, and other industries, as well as the washing of fine and coarse-grained materials.

Specifications of Wheel Type Sand Washer

| Model | Feeding Size (mm) | Capacity (t/h) | Impeller Size (mm) | Power (kw) | Overall Size (mm) |

| XSD1808 | ≤10 | 20-40 | 1800*800 | 3 | 3000*2400*1900 |

| XSD2512 | ≤10 | 30-80 | 2500*1200 | 4 | 3900*2900*2700 |

| XSD3016 | ≤10 | 60-120 | 3000*1600 | 5.5 | 4400*3300*3100 |

| XSD3620 | ≤10 | 80-160 | 3600*2000 | 7.5 | 5100*3750*3700 |

| XSD3624 | ≤10 | 120-200 | 3600*2400 | 11 | 5100*4100*3700 |

Features of Shunzhi Spiral Sand Washer

High working efficiency

The washed materials have less loss and high washing efficiency, which can fully meet the requirements of high-grade materials.

Less maintenance needed

The bearing shall be separated from water and materials to avoid damage to the machine caused by early pollution and rust, and nearly no wearing parts included ensures less maintenance needed during long working hours.

Applicable to various working environments

The washed materials have less loss and high washing efficiency, which can fully meet the requirements of high-grade materials.

Specifications of Spiral Sand Washer

| Model | Feeding Size (mm) | Capacity (t/h) | Spiral Diameter (mm) | Spiral Shaft | Tank Length(mm) | Power (kw) | Overall Size (mm) |

| LX0920 | ≤10 | 30-60 | 920 | 1 | 8000 | 11 | 8710*1630*2080 |

| LX1120 | ≤10 | 40-80 | 1120 | 1 | 8000 | 18.5 | 9230*1840*2130 |

| LX1500 | ≤10 | 50-100 | 1500 | 1 | 8000 | 22 | 9620*2230*2480 |

| 2LX0920 | ≤10 | 60-120 | 920*2 | 2 | 8000 | 11*2 | 8710*2600*2080 |

| 2LX1120 | ≤10 | 80-160 | 1120*2 | 2 | 8000 | 18.5*2 | 9230*3050*2130 |

| 2LX1500 | ≤10 | 120-250 | 1500*2 | 2 | 8000 | 22*2 | 9620*3730*2480 |

Features of Shunzhi Fine Sand Reclaimer

Less loss of finess

The fine sand reclaimer can effectively reduce the loss of fineness and control it within 5% – 10%, which solves all problems with high- Fineness modulus finished aggregate or low content for artificial stone powder in processing systems.

Long service life

The polyurethane screen used for vibrating screen has longer service life than other types of screens and will not block holes.

Cyclone lined with polyurethane

By lining cyclone with polyurethane, the service life of the whole device is greatly improved, and in working, it can successfully complete slurry concentration, liquid clarification, etc.

Specifications of Fine Sand Reclaimer

| Model | Separator Specification | Size of Dewatering Screen(mm) | Dehydration Screen Power(kw) | Type of Pump | Pump Power(kw) | Capacity(tph) |

| SZ8018 | 250 | 800*1800 | 0.75*2 | 2-3 | 11 | 5-10 |

| SZ1020 | 300 | 1000*2000 | 1.1*2 | 3-4 | 15 | 10-20 |

| SZ1225 | 350 | 1200*2500 | 2.2*2 | 3-4 | 15 | 20-30 |

| SZ1530 | 350*2 | 1500*3000 | 3.0*2 | 3-4 | 15*2 | 50-80 |

| 2SZ1530 | 350*2 | 1500*3000 | 3.7*2 | 3-4 | 15*2 | 50-100 |

| SZ1840 | 350*2 | 1800*4000 | 3.7*2 | 3-4 | 15*2 | 100-130 |

| 2SZ1840 | 350*2 | 1800*4000 | 3*4 | 3-4 | 15*2 | 100-150 |

| SZ2050 | 500*2 | 2000*5000 | 3.7*4 | 3-4 | 18.5*2 | 150-200 |

| 2SZ2060 | 500*2 | 2000*6000 | 3.7*4 | 2-3 | 22*2 | 200-260 |

What Do Customers Talk About Us?

Hard to find such a professional team like Shunzhi sale team again! They offer detailed solutions based on our needs and their machines are really in the best quality.

– Temuge Otichigin

We used the sand washer from Shunzhi for multiple projects, and they perform excellently in each project.

– Dayir Usun

Frequently Asked Questions

Featured Products

Shunzhi Hammer Crusher

Shunzhi hammer crusher is suitable for crushing hard and medium hard materials in many industrial departments such as cement, chemistry, power station and metallurgy. The working principle is…