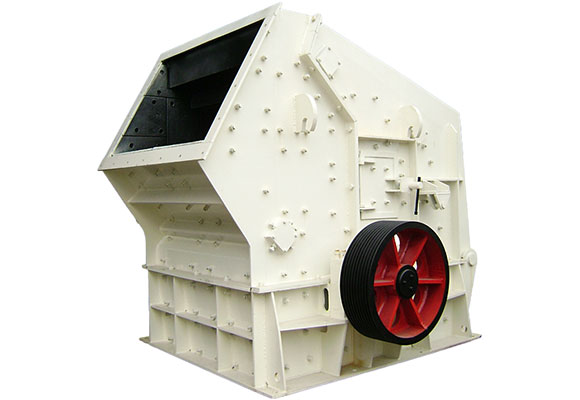

Shunzhi Impact Crusher

57% of operation cost reduction and 29% of working efficiency improvement, Shunzhi impact crusher machine is a new type of broken equipment designed by our company. It adopts international advanced technology and unique structural design.

The impact crusher is widely used in mining, highway and railroad construction, refractories, power plants, cement plants and other fields.

Impact Crushers For Sale

Shunzhi impact crusher plant – Designed For Primary & Secondary Crushing.

Feeding Size: ≤500mm

*Note: Can Be Customized.

Capacity: 30-400t/h

*Note: Can Be Customized.

Applicable Materials:

Our impact crusher is perfect for handling a wide range of materials – from limestone, granite and marble to basalt, iron ore or river pebbles. It’s also capable of withstanding pressures up to 250 mpa – ideal for even the toughest jobs such as coal cobblestones and construction waste!

Applicable Fields:

Widely used in various ore crushing, mining, metallurgy, building materials, highway, railway, chemical, construction, and other industries.

What Are Impact Crushers?

An impact crusher is a piece of heavy construction equipment that is designed to reduce the size of large material, like rocks and stone, into smaller aggregate such as gravel, sand or dust. The process works by using force that is applied abruptly to the mass or volume of the material, hence the name ‘impact crusher’.

This machine is generally used in the mining, quarrying, and recycling industries. It’s particularly useful for materials that are soft and non-abrasive such as limestone, coal, gypsum, weathered shales, and phosphate.

Types of Shunzhi Impact Crushers for Sale

Shunzhi has impact crushers (PF impact crusher), European crushers (PFW impact crusher) and mobile impact crushers for sale. All three types of crushing machines can be well used in aggregate production, mining operation, cement making, sand and gravel production, and recycling industry.

Compact, powerful and with easy transport dimension, high capacity, Shunzhi impact crusher is very popular for many business owners and customers.

PF Impact Crusher for Sale

The impact crusher is a crushing machine that uses the impact of the rotor to crush the material.

The PF impact crusher is a commonly used machine in many industries. It can break all kinds of materials with compressive strength not exceeding 350 MPa, such as granite, limestone, concrete, etc.

This machine is ideal for primary and secondary crushing, construction, concrete recycling and so on.

| Model | PF-1007 ~ PF-1820 |

| Specification (mm) | 1000×700 ~ 1260×2040 |

| Capacity (t/h) | 30-70 ~ 400-800 |

European Impact Crusher for Sale

The European impact crusher, or PFW impact crusher is a new generation of impact crusher from Shunzhi and is the most advanced equipment in the field of crushing machines.

Compared with the traditional PF impact crusher, European impact crusher or PFW impact crusher improves the crushing efficiency and continuously reduces the operating costs.

The PFW impact crusher features a unique three-dimensional design, which not only improves the crushing efficiency but also makes the finished product more beautiful.

In addition, its max feed size reaches 550mm, greatly enhancing the production capacity.

| Model | PFW1007-Ⅱ ~ PFW1320-Ⅱ, PFW1007-Ⅲ ~ PFW1320-Ⅲ |

| Specification (mm) | 1000×700 ~ 1260×2040 |

| Capacity (t/h) | 40-90 ~ 230-450, 15-60 ~ 160-350 |

Mobile Impact Crusher for Sale

Mobile impact crusher is a multi-functional machine, which has features of a large crushing ratio, uniform particle size, simple structure, reliable performance and easy maintenance.

With a compact structure and smooth wheel or crawler, Shunzhi mobile crusher is easy to transport from site to site.

This machine is widely used in mining, metallurgy, chemical, building materials, highway, railway, water conservancy and so on.

| Model | SZFY1007 ~ SZFY1520 |

| Maximum feeding (mm) | 300 ~ 700 |

| Capacity (t/h) | 85 ~ 400 |

Small Impact Crusher for Sale

The small impact crusher, often referred to as a mini impact crusher, is a compact yet powerful piece of equipment.

Despite its smaller size, the mini-impact crusher is widely used in various industries such as mining, metallurgy, construction, and recycling. It efficiently crushes different types of materials, including ores, rocks, and construction waste.

Its compact size makes it particularly suitable for smaller operations and projects where space is limited, or where frequent relocation is required.

| Model | PF1007 ~ PF1210 |

| Maximum feeding (mm) | 300 ~ 350 |

| Capacity (t/h) | 30 ~ 130 |

More Working Modes.

Impact crushers are renowned for their ability to effortlessly handle materials with high wet capacities. For materials that contain too much water a heating device can be installed in key locations on both impact plates and feed chutes to break down bonded materials.

More Flexible.

With an impact crusher, you can easily find the optimum particle size for your product! Through customized rotor speed and distance adjustments between the grinding chamber and impact plate, this equipment offers a customizable approach to achieving desired results.

More Wear Resistant.

The Impact crusher boasts impressive wear-resistance, allowing it to maintain its performance with minimal upkeep. As a result of the rotor speed’s optimal operation and low feed rate, other parts require little maintenance—leading to cost savings on replacements while improving overall metal utilization.

More Convenient.

Impact crusher maintenance is streamlined and effortless; the only component prone to wear-and-tear, the blow bar, can be replaced with a specialized tool designed for easy replacements.

Our Advantages

Shunzhi impact crusher receives overwhelmingly positive responses. Its unique design, efficient crushing performance and stable operation have won the trust of customers.

Applied the latest technology in its design & equipped powerful motor, our crusher improves efficiency by an additional 41%.

+41%

High Efficiency

With a saw tooth type counterattack liner, Shunzhi impact crusher can crush even the hardest rocks and materials with ease.

40%

Large Crushing Ratio

Shunzhi impact crusher uses less energy and is easy to maintain. With the hydraulic design, it is convenient to replace the worn parts.

57%

Operation Cost Saving

The modular design of the side liner in Shunzhi impact crushers allows for easy replacement and interchangeability.

75%

Liner Interchange Rate

Why Choose Shunzhi Impact Crushers?

Traditional Impact Crushers

30% Crushing Ratio.

700mm Max Feeding Size.

30 – 550 t/h Capacity.

400×730 mm ~ 830×2040 mm Feed Opening.

Shunzhi Impact Crushers

40% Crushing Ratio.

800mm Max Feeding Size.

15 – 800 t/h Capacity.

400×730 mm ~ 1260×2040 mm Feed Opening.

Shunzhi Impact Crusher Price List

| Types | Price Range |

| PF Impact Crusher | $1,000 – $50,000 |

| European Impact Crusher | $2,100 – $70,000 |

| Mobile Impact Crusher | $5,000 – $130,000 |

| Small Impact Crusher | $1000 – $30,000 |

The price of Shunzhi impact crusher are only for reference, according to different configurations, the price will vary.

The Shunzhi impact crusher has many features that make it a great choice for businesses and consumers. If you are interested in our impact crusher, get a free quote now. We would be happy to provide you with everything based on your specific needs.

How Shunzhi Impact Crusher Save Your Cost?

Investing in an impact crusher requires careful financial consideration. While the initial cost is a crucial factor, it’s equally important to consider the long-term operational and maintenance costs. Shunzhi’s high-quality impact crushers offer a compelling case in this regard.

Shunzhi impact crusher’s superior design and construction ensure better efficiency, lower operational costs, and less frequent maintenance needs.

| Attributes | Shunzhi’s Impact Crushers |

|---|---|

| Initial Cost | Shunzhi offers the factory price and the impact crusher is affordable. |

| Operational Cost | Lower operational cost due to energy-efficient design and less wear and tear. |

| Maintenance Cost | Maintenance cost is lower, thanks to durable parts and easy accessibility for servicing. |

| Technology & Features | Equipped with cutting-edge technology for improved efficiency and safety. |

| Lifespan | Exceptionally long lifespan due to robust construction and high-quality materials. |

| Customer Support | Outstanding customer support with prompt service and comprehensive after-sale services. |

Shunzhi’s impact crushers represent a wise investment for those seeking a balance between upfront costs and long-term savings.

Our remarkable efficiency, durability, and customer support make them a valuable addition to any operation.

Features of Shunzhi Impact Crusher

Shunzhi impact crusher has many advantages, such as high efficiency, good particle size control, long service life of plate hammer, and so on. It is also very adaptable and can be used in many different industries.

No Blockage

The rotor is driven by the motor and has high-speed rotation when it works. When the materials are flow into the plate hammer region, they may be crushed by the rotor’s plate hammer. After that, the materials are sent to a hammer where they have been crushed again and broken by a hammer.

The procedure is repeated until all of the material that needs to be crushed has been satisfied. In this way, Shunzhi impact crusher guarantees no blockage when it works.

Fully Control of Particle Size

Because of the adjustable plate and hammer clearance, The finished particle size and its properties can all be controlled to a significant extent.

Long Service Life of Plate Hammer

Shunzhi impact crusher adopts high-chromium plate hammer and unique structure design. The durability is significantly improved, and the service life of plate hammer will be prolonged effectively.

Reliable Performance and Good Shape

Shunzhi impact crusher is capable of highly efficient hard rock crushing while saving energy. The end products have good shape. It has been proved that this machine not only effectively increases productivity and final product quality, but also reduces the investment cost and saved energy.

Wide Adaptability

Shunzhi impact crusher can be widely used in different kinds of hard and brittle materials such as granite, basalt, cobble stone, quartz stone and iron ore, coal mining, and metallurgy industry, chemical industry, cement and other industries.

If you’re interested in our impact crushers, please click here to contact us. We would be happy to discuss your specific needs and recommend the best crusher for your application.

Types of Shunzhi Impact Crusher

Impact crushers come in a variety of shapes and sizes, depending on your industry. Here are some of the most common types of impact crushers:

• Vertical Shaft Impactor (VSI):

This type of impactor is typically used to process medium to hard materials such as granite and limestone. The VSI uses centrifugal force to throw material against a wall or another surface. It is generally used for softer materials, such as sandstone and limestone.

• Horizontal Shaft Impactor (HSI):

This type of impactor is typically used to process harder materials such as basalt and granite. The HSI uses a hammer to break material against an anvil or other surface, which results in more efficient crushing than VSI crushers.

• Hammermill Crusher:

This type of crusher is commonly used in quarries or mines, but can also be used in recycling applications. It works by using hammers to crush material against a spinning disk or rotor blade. The rotor blades are usually made from high wear-resistant steel alloys or chromium carbide, depending on the application.

Applications Impactor Crushers

Impact crushers have a wide range of applications in various industries such as mining, quarrying, construction, demolition, recycling, and asphalt production.

They’re especially useful in the mining industry where they can be used to reduce rocks into smaller pieces that are easier to transport or work with.

In the construction industry, impact crushers can be used in demolition projects to break apart concrete structures quickly and safely.

They can also be used in recycling projects where they help reduce waste materials into usable products like gravel or crushed stone.

Finally, they’re great for asphalt production because they help produce consistent sizes and shapes when breaking apart rocks for use in paving roads or other surfaces.

Components of Impact Crusher

Attention to detail is key when crafting an impact crusher of quality and excellence. Each component contributes in a unique way to the full assembly: from the spring providing support, through the square steel that forms its frame -all leading up to the plate hammer which serves as one of its most important features. But it doesn’t end there- locking block, compression block, and more also add layers crucial to compact construction cohesion!

1. Blow hammer

For any heavy-duty task, a blow hammer is an essential tool. Its precise shape and hardy material allow for reliable usage and improved metal utilization rates with lesser maintenance requirements.

2. Compression block

Compressing blocks too play an important role in mining machinery; they are known to be heat treated under controlled conditions resulting in excellent wear resistance as well as increased strength levels.

3. Counterattack

With the help of an impact plate and its resilience, material is broken through a reciprocal process. To enable this procedure to progress efficiently, these plates are designed using steel with wear-resistant lining for increased endurance against heavy impacts from materials.

4. Rotor

Impact crushers boast an impressive construction quality, with rotors composed of cast steel or welded from plates. Not only are they reliable and robustly built but also easy to install in any environment – making them a popular choice among quarries around the world.

5. Square steel

Professionally crafted Square Steel can deliver superior crushing performance with high strength and wear resistance. Engineered using a rigorous heat treatment process, this material provides unbeatable investment benefits while ensuring uncompromising durability in any application.

Global Cases

Impact Crusher Installed in Kenya

Our customer from Kenya bought an impact crusher of model PF1210 to produce 40-60mm aggregate. The crusher run smoothly and achieved the expected output. The customer was very pleased with the results and our service.

Impact Crusher Installed in Ghana

One of our Ghana customers praised our impact crusher for its good performance and low maintenance cost. Our customers use the impact crusher to process granite, limestone, concrete, etc., for construction and road repair.

Impact Crusher Sent to Malaysia

Shunzhi impact crusher is sent to Maylasia to provide crushing and sand making production line for local infrastructure construction. Our machine is welcomed because of its simple structure, strong working performance and low investment cost.

Impact Crusher Works in Tanzania

Our impact crushing machine is sent to Tanzania to help our customers crush the limestone. This impact crushing equipment is used in the secondary crushing process and has a great performance with low consumption.

Specifications

| Model | Specification(mm) | Feed Opening(mm) | Max Feeding Size(mm) | Capacity(t/h) | Power(kw) | Overall Dimension(L x W x H)(mm) | Total Weight(t) |

| PF-1007 | 1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330x1660x2300 | 12 |

| PF-1010 | 1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370x1700x2390 | 15 |

| PF-1210 | 1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680x2160x2800 | 17.7 |

| PF-1214 | 1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650x2460x2800 | 22.4 |

| PF-1315 | 1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180x2720x3120 | 27 |

| PF-1320 | 1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220x3100x3120 | 34 |

| PF-1520 | 1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959x3564x3330 | 50.6 |

| PF-1820 | 1800×2000 | 1260×2040 | 800 | 400-800 | 4P 630-710 | 4400x3866x4009 | 83.2 |

Working Principle of Impact Crusher

The working principle of an impact crusher is relatively simple. When a material enters the chamber, the rotor rotates at a high speed and applies force to the material.

This results in the material being broken down into smaller particles that are then discharged from the machine.

The particles are then conveyed via conveyor belts or other means to another processing station for further refinement or disposal.

Getting High Quality Impact Crusher Prices

In the thriving sectors of industrial development and construction, impact crushers play a critical role in material processing. As you venture into purchasing a impact crusher, here are some vital points to help secure better equipment at a superior price.

Define Your Project Needs

Before you set out to buy a impact crusher, it’s essential to clearly establish your requirements. These include the type of material you’ll be processing, the desired output, and the required particle size. This fundamental step helps in accurately determining the specifications and capabilities of the equipment you need.

At this stage, a professional supplier can offer customized solutions based on a deep understanding of your needs. A diligent team will ensure that the chosen equipment aligns with your specific requirements and yields optimal crushing results.

Consider the Overall Cost

In addition to the initial purchase price, you must also consider the operational and maintenance costs, as well as the longevity of the equipment. Opting for equipment with an excellent energy consumption ratio, easy maintenance, and durability can reduce long-term operational costs.

Look for

crushers designed with optimal energy consumption and minimal maintenance costs. Advanced technology and careful material selection can ensure efficient energy use and lower your overall costs.

Review Warranty Terms and Contracts Thoroughly

Before completing your purchase, carefully review the warranty terms and details of the contract. Understanding key elements such as the warranty period, scope of liability, and repair process is crucial to protect your rights and interests.

Ensure that the warranty terms and contracts are clear and detailed, providing comprehensive warranty services. A reputable supplier will take responsibility for the maintenance and support of the equipment during the warranty period to ensure its smooth operation.

Partner with a Trusted Supplier

Ineed, it’s essential to partner with a supplier that brings a wealth of experience and a track record of superior service. Shunzhi has a rich history of serving customers for over 30 years, consistently delivering high-quality products and exceptional service.

Our commitment to customer satisfaction and continual improvement has made us a trusted partner for businesses worldwide. By choosing to cooperate with us, you’re not just investing in top-class equipment but also gaining a reliable partner dedicated to boosting your business success.

With Shunzhi, you can look forward to a future of efficient operations and positive growth. Let’s work together to create a prosperous future for your business.

What Do Customers Talk About Us?

The company has a strict quality control system and perfect after-sales service. It is a reliable supplier for users. Shunzhi impact crusher we got is simple to operate and easy to maintain.

Its efficiency is so high and can help us produce more. The product quality meets our requirements for stone crushing production. We have been using it for some time and there is no problem with it.

– Thomas Sithole

We are pleased with the good results Shunzhi impact crusher brings to us. The equipment is stable in performance, energy efficient, environmentally friendly and high quality in finished products.

It has brought great benefits to our production, saved a lot of production costs and labor costs, and helped us win the market. We will continue to cooperate with Shunzhi Machinery in the future.

– Khun Sein Shwe

Frequently Asked Questions

Featured Products

Shunzhi Hammer Crusher

Shunzhi hammer crusher is suitable for crushing hard and medium hard materials in many industrial departments such as cement, chemistry, power station and metallurgy. The working principle is…