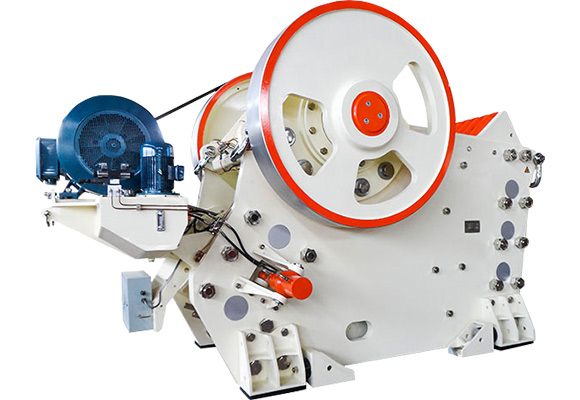

Shunzhi Jaw Crusher

With 36% less operating costs and 46% working performance, Shunzhi jaw crusher keeps the leading position in the mining market.

It adopts advanced technology to reduce 15%-20% energy consumption and guarantee uniform product granularity, which makes it a wise choice for crushing various ores and bulk materials in mining smelting, building materials, highways, railways, water conservancy, and chemical industries.

Primary Jaw Crusher For Sale

From Large 500-1000t/h Jaw Crusher to 10-100t/h Small Jaw Crusher – Applicable to more than 200 materials and applied in many fields.

Feeding Size: ≤750mm

*Note: Can Be Customized.

Capacity: 1-1000t/h

*Note: Can Be Customized.

Applicable Materials:

Quartz, granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, coal, concrete, gold ore etc.

Applicable Fields:

Show excellent performance in various industries, such as mining, road and railway construction, building construction,water conservation and chemical industry etc.

What Are Jaw Crushers?

A jaw crusher is a type of heavy-duty machine used in construction and mining industries. It’s primarily utilized in the first step of reducing large pieces of material into smaller, more manageable fragments. It’s particularly effective in breaking down hard materials such as granite, basalt, and ores.

The jaw crusher finds extensive applications in various sectors such as mining, infrastructure & building, highways, and railways, among others. It’s particularly favored for its ability to process materials with high toughness and large block size, which other crushers may struggle with.

Types of Jaw Crushers for Sale

Three types of jaw crushers are now available in shunzhi, including the PE series jaw crusher, European jaw crusher, and mobile jaw crusher, all of which can meet the needs of customers for primary crushing.

Shunzhi’s PE series jaw crushers are widely used in Mining, metallurgy, construction, highway, railway, water conservancy, chemical industry, and other fields. The European jaw crusher developed by Shunzhi is specially designed for tough materials. It is suitable for the primary crushing of various kinds of ores and rocks with compressive strength not exceeding 320 MPa. The mobile jaw crusher developed by Shunzhi is suitable for both primary and secondary crushing. It can be used in mining, metallurgy, construction, highway, railway, water conservancy, and chemical industries.

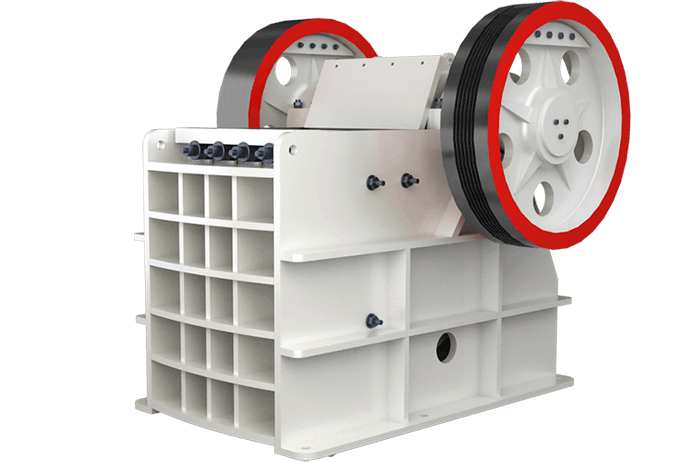

PE Series Jaw Crusher for Sale

The PE series jaw crushers are one of the most popular types of primary rock crushing machines in various industries such as mining, quarrying, and construction sites.

They are designed to crush large rocks into smaller pieces suitable for secondary crushing using either compression or shearing action.

These versatile machines can be used in a wide range of applications ranging from 80 – 875 tons/hour depending on the model and settings.

| Model | PE-150×250~PE-1500×1800, PEX-150×750~PEX-300×1300 |

| Feed opening(mm) | 150×250~1500×1800, 150×750~300×1300 |

| Processing Capacity(t/h) | 1-3~500-1000, 8-25~16-105 |

European Jaw Crusher for Sale

The European jaw crusher is a highly advanced piece of equipment that has been designed to cater to the most rigorous crushing needs.

It was built with input from experts in construction engineering, who recommend its use when it comes down to finding suitable material sizes and layouts within airports or other large-scale projects like highways/railways etc., where they need high-impact facilities but also something capable enough against hard minerals such as granite rocks which can easily cause wear.

| Model | CJ96 ~ CJ1513 |

| Maximum Feed Size(mm) | 480-1040 |

| Processing Capacity(t/h) | 10 ~ 100 tph |

Mobile Jaw Crusher for Sale

The mobile jaw crusher is a versatile tool that can be used in a variety of applications. The most common use is for primary crushing, but it can also be used as a secondary crusher or even a tertiary crusher.

Depending on the application, the mobile jaw crusher can either be powered by electricity or diesel.

The mobile jaw crusher is a highly flexible and economical machine that can be easily moved from one production site to another. It also works with other Shunzhi machines, such as stationary grinders or screens; forming complete lines for efficient operations at lower costs than traditional methods!

| Model | SZEL69, SZEL106, SZEL120 |

| Crusher Model | PE600x900, PE750x1060, PE900x1200 |

| Size of Feed Inlet(mm) | 930×580, 1060×700, 1200×870 |

Small Jaw Crusher for Sale

The small jaw crusher, often referred to as a mini jaw crusher, is a compact yet powerful piece of equipment.

Despite its smaller size, the mini jaw crusher is widely used in various industries such as mining, metallurgy, construction, and recycling. It efficiently crushes different types of materials, including ores, rocks, and construction waste.

Its compact size makes it particularly suitable for smaller operations and projects where space is limited, or where frequent relocation is required.

| Recommended Model | PE150x250 ~PE400x600, PEX150x750~PEX300x1300 |

| Maximum Feed Size(mm) | ≤450mm |

| Processing Capacity(t/h) | 1 ~ 100 tph |

More Effective.

Adjusting crushing chamber and trajectory settings of the moving jaw enables more effective inertia momentum and a better quality crush, resulting in improved performance with little additional energy expenditure.

More Compact.

By utilizing bolted fastening instead of welding, this structure offers a more compact size while avoiding stress concentration points that could be caused by the welding process.

More Durable.

By replacing its anchor connection with elastic position limiters and rubber damping, the crusher has improved durability by lessening the impact on other components.

More Convenient.

High-quality materials and components are selected to maximize cost efficiency, with main parts easily interchangeable for convenient maintenance.

Our Advantages

Shunzhi jaw crushers win pride in all of our customers because of our premium quality level and high technology design, we are here to give you the optimal solutions based on your needs.

The jaw crusher has a deep crushing chamber which improves its feeding capacity. This means more material can be crushed at once, increasing productivity to large extent!

1160t/h

FEEDING CAPACITY

Large crushing ratio on our jaw crusher deals with hard rocks at ease with uniform particle size output, greatly improving working efficiency and reducing unnecessary costs.

99%

uniform particle size

The large adjustment range of the gasket-type adjusting device of the discharge port effectively increases the flexibility of the crusher machine and caters to any requirements.

+21%

flexibility of machine

Simple structure design with the sturdy internal material reduces 36% operation costs and maintenance costs.

enabling you to get investment back just in short period of time.

-30%

operation costs

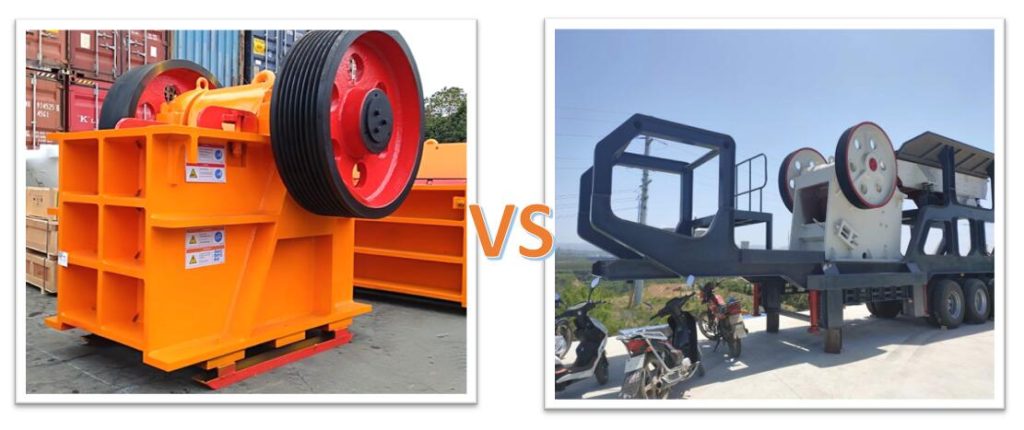

Stationary Jaw Crusher, Or Mobile Jaw Crusher?

Stationary Jaw Crushers

Easy to maintain because it does not require frequent adjustments like most other types of crushers do.

Offer high productivity and efficiency because they can process large amounts of material at once without requiring frequent stops for refueling or maintenance.

Come with safety features such as emergency stop buttons, which allow you to shut down the machine quickly if something goes wrong.

Designed to withstand harsh working conditions and can last much longer than other types of crushers.

Mobile Jaw Crushers

Incredibly flexible, allowing you to move them from one job site to another without much trouble.

Can be transported easily from one location to another without requiring additional space or manpower to move them around – saving you time and money on labor costs.

Ideal for use in a variety of applications from quarrying to demolition work, road building, and more.

More affordable than stationary ones, but they also require less maintenance over time.

Shunzhi Jaw Crusher Price List

| Types | Price Range |

| PE Jaw Crusher | $1,000 – $15,500 |

| European Jaw Crusher | $1,800 – $50,000 |

| Mobile Jaw Crusher | $28,000 – $130,000 |

| Small Jaw Crusher | $1,000 – $10,000 |

The most important factor in determining the jaw crusher price is its capacity. A higher capacity means a higher price.

There are many other factors that will affect the final price, such as delivery time and installation cost. If you want to know the specific jaw crusher price, please contact us for a free quote!

How Shunzhi Jaw Crusher Save Your Cost?

Investing in a jaw crusher requires careful financial consideration. While the initial cost is a crucial factor, it’s equally important to consider the long-term operational and maintenance costs. Shunzhi’s high-quality jaw crushers offer a compelling case in this regard.

Shunzhi jaw crusher’s superior design and construction ensure better efficiency, lower operational costs, and less frequent maintenance needs.

| Attributes | Shunzhi’s Jaw Crushers |

|---|---|

| Initial Cost | Shunzhi offers the factory price and the jaw crusher is affordable. |

| Operational Cost | Lower operational cost due to energy-efficient design and less wear and tear. |

| Maintenance Cost | Maintenance cost is lower, thanks to durable parts and easy accessibility for servicing. |

| Technology & Features | Equipped with cutting-edge technology for improved efficiency and safety. |

| Lifespan | Exceptionally long lifespan due to robust construction and high-quality materials. |

| Customer Support | Outstanding customer support with prompt service and comprehensive after-sale services. |

Shunzhi’s jaw crushers represent a wise investment for those seeking a balance between upfront costs and long-term savings.

Our remarkable efficiency, durability, and customer support make them a valuable addition to any operation.

How Shunzhi Jaw Crusher Improves Your Business?

Integral cast steel structure

The bearing block is designed with an integral cast steel structure that ensures a perfect fit against the crushing frame, greatly increasing its radial strength.

Eccentric shaft bearings

The eccentric shaft bearings in this series are larger and more durable than other crushers of the same specification. Their higher bearing capacity, and effective labyrinth seals that reduce noise for a quiet operation- these features together greatly extend their service life!

Symmetrical “v” structure

To ensure the even distribution of particles, the crushing chamber has an “v” shaped design. This means that both widths are consistent with one another and no matter which way you look at it there will always be enough space for your material in this area!

World-class manufacturing process

Our jaw crusher is manufactured using world-class manufacturing processes and high-end materials. This ensures that our jaw crusher is durable and reliable. Additionally, our jaw crusher is designed for maximum efficiency and performance.

And, thanks to the use of high-end materials, our jaw crusher is able to handle even the most challenging crushing applications.

Global Cases

European Jaw Crusher Works in the Philippines

Last month, a European jaw crusher produced by us has been sent to Lingayen, Dagupan, the Philippines. At present, the equipment has been used for several months.

Jaw Mobile Crushing Station Sent to South Africa

Congratulations! Our jaw mobile crushing station was sent to South Africa in 2020. After 2 years of working, it is now still in excellent working performance.

Jaw Crawler Mobile Crushing Station Sent to Kenya

We are very glad that our crawler mobile jaw crushing station has been put into use in Kenya. The equipment was delivered in December 2021.

PE-1200×1500 Jaw Crusher Works in Pakistan

The latest good news coming! The PE-1200×1500 jaw crusher ordered by a customer from Pakistan was already packed and to be sent.

Specifications

| Model | Feed opening(mm) | Max feeding size(mm) | Adjusting range of discharge opening(mm) | Processing capacity(t/h) | Rotation speed of eccentric shaft(r/min) | Motor power(kw) | Total weight(t) |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 250 | 4P 5.5 | 0.8 |

| PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 1.2 |

| PE-200×350 | 200×350 | 180 | 18-70 | 3-10 | 260 | 4P 11 | 1.5 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-21 | 300 | 6P 15 | 2.8 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-64 | 275 | 6P 30 | 7 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 6P 55 | 12 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-160 | 250 | 6P 55 | 17 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 8P 110 | 29 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 200 | 8P 160 | 52 |

| PE-1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 200 | 8P 200 | 55 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 180 | 6P 160-240 | 100.9 |

| PE-1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1000 | 180 | 8P 355 | 139 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 3.8 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 330 | 6P 22 | 5.5 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 7 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 9.7 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 15.6 |

Working Process of Jaw Crusher

A jaw crusher is a machine that is used to reduce the size of many different types of materials in many applications. The jaw crusher has two plates, or jaws, with one being fixed and the other moving. The moving jaw plate is mounted on an eccentric shaft which moves it back and forth relative to the stationary plate. Knowing how it works is important for any buyer who needs a jaw crusher for their business or construction site.

The working principle of the jaw crusher is based on the reciprocating movement of the movable jaw plate that compresses and crushes objects like rocks and other materials placed between the fixed and moveable plates. The movable jaw plate moves back and forth against the fixed one, repeatedly reducing and breaking down hard materials until they are small enough to pass through a narrow opening at the bottom.

The force applied to break down objects is determined by two factors: the size of the gap between the two plates (known as “the discharge space”) and the speed at which they move back and forth (known as “stroke”). As these two variables change, so does the output size of crushed material.

Jaw crushers are also equipped with safety mechanisms that prevent damage to both machines and users when operating them. Many modern jaw crushers include built-in sensors that detect any movement in their components, allowing operators to quickly shut down or adjust operations before any accidents occur. These sensors also help prevent wear and tear on machine parts over time by providing feedback about their condition.

In conclusion, it’s clear why a jaw crusher is such an important piece of equipment for many industries—it offers both efficiency and safety in a single, easy-to-use device. Whether you’re looking for a primary or secondary crusher for your project, understanding how a jaw crusher works is essential for selecting one that fits your needs perfectly. With this knowledge in hand, you’ll be able to choose from among different models with confidence knowing that you have made an informed decision about which model is best for your specific application needs.

Getting High Quality Jaw Crusher Prices

In the thriving sectors of industrial development and construction, jaw crushers play a critical role in material processing. As you venture into purchasing a jaw crusher, here are some vital points to help secure better equipment at a superior price.

Define Your Project Needs

Before you set out to buy a jaw crusher, it’s essential to clearly establish your requirements. These include the type of material you’ll be processing, the desired output, and the required particle size. This fundamental step helps in accurately determining the specifications and capabilities of the equipment you need.

At this stage, a professional supplier can offer customized solutions based on a deep understanding of your needs. A diligent team will ensure that the chosen equipment aligns with your specific requirements and yields optimal crushing results.

Consider the Overall Cost

In addition to the initial purchase price, you must also consider the operational and maintenance costs, as well as the longevity of the equipment. Opting for equipment with an excellent energy consumption ratio, easy maintenance, and durability can reduce long-term operational costs.

Look for jaw crushers designed with optimal energy consumption and minimal maintenance costs. Advanced technology and careful material selection can ensure efficient energy use and lower your overall costs.

Review Warranty Terms and Contracts Thoroughly

Before completing your purchase, carefully review the warranty terms and details of the contract. Understanding key elements such as the warranty period, scope of liability, and repair process is crucial to protect your rights and interests.

Ensure that the warranty terms and contracts are clear and detailed, providing comprehensive warranty services. A reputable supplier will take responsibility for the maintenance and support of the equipment during the warranty period to ensure its smooth operation.

Partner with a Trusted Supplier

Ineed, it’s essential to partner with a supplier that brings a wealth of experience and a track record of superior service. Shunzhi has a rich history of serving customers for over 30 years, consistently delivering high-quality products and exceptional service.

Our commitment to customer satisfaction and continual improvement has made us a trusted partner for businesses worldwide. By choosing to cooperate with us, you’re not just investing in top-class equipment but also gaining a reliable partner dedicated to boosting your business success.

With Shunzhi, you can look forward to a future of efficient operations and positive growth. Let’s work together to create a prosperous future for your business.

What Do Customers Talk About Us?

Bought several sets of jaw crusher from Shunzhi and use them in our crushing plant for 1 year. The results show that their machines are very stable and efficient.

– Guney Mashwanis

I use the jaw crushers from Shunzhi to deal with stone crushing in my mining industry, hard to find such an efficient machine again. Will work with them again!

– Fardan Lodhra

Frequently Asked Questions

Featured Products

Shunzhi Hammer Crusher

Shunzhi hammer crusher is suitable for crushing hard and medium hard materials in many industrial departments such as cement, chemistry, power station and metallurgy. The working principle is…