Shunzhi Mining Crusher Plant

Shunzhi mining crusher plants feature up to 38% faster crushing speeds, powering through even the hardest stones.

Our mining crusher plant is widely used in aggregate production, ore crushing and other fields to crush gravel, granite, boulder, limestone, etc.

Get the customized crushing capacity you need from 5 to 1000 tons per hour for your particular application with Shunzhi.

Mining Crusher Plant For Sale

Large capacity Shunzhi mining crusher plant – 20TPH, 50TPH, 100TPH, 200TPH, 500TPH In Large Stock!

Feeding Size: 0-300mm

*Note: Can Be Customized.

Capacity: 5-1000t/h

*Note: Can Be Customized.

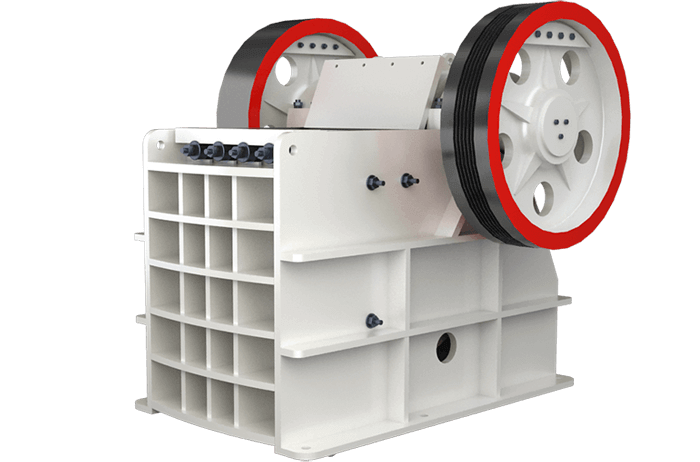

Available Crusher Type for Mining

Other Applicable Fields:

Widely used in recycling and reusing coal mines, iron ore, construction demolition waste, and other resources.

More Efficient.

The plants use advanced grinding systems and sensors to optimize their operations and lower energy consumption.

Less Waste.

The mining crusher plant creates very little waste since most materials are recycled into new products or reused in other projects. .

More Safe In Use.

Modern mining crushing plants also come with enhanced safety features that help protect your workers from potential dangers when operating the machines.

More Precise.

The machines used in the process can be programmed to produce materials with accurate measurements and precise textures.

Portable Mining Crusher, Or Stationary Crusher Plant?

Portable Mining Crushing Plant

It allows for flexibility and ease of use, as the equipment can be moved around to different locations or even relocated entirely if needed.

The portability of mobile mining crushing plants makes them an ideal solution for smaller operations that may not have the space or resources for a larger plant.

More suitable for lower budget, for they costs less than stationary type.

More easily maneuvered over uneven terrain or dirt roads. This makes it ideal for use in quarries or other rugged areas.

Fixed Mining Crushing Plant

Stationary/fixed mining crushing plants are typically larger in size and require more planning for set-up and transport between sites.

They also tend to be more expensive due to their higher capacity, making them better suited for larger operations.

Does not require tires or tracks to move around.

Offers greater consistency in production as the output size and type is predetermined.

Our Advantages

Shunzhi mining crusher plant has a complete after-sales service system for customers, providing customers with technical advice, installation guidance, and maintenance instructions. We are committed to providing our customers with quality products and services. Welcome to visit our company for negotiation.

50% large crushing ratio of our plant is able to produce high-quality aggregate for large-scale construction projects. We also use advanced technology to reduce noise and dust pollution, meeting the standards set by local environmental protection agencies.

50%

CRUSHING RATIO

Our mining crusher plant is designed to produce high-quality and consistent results with minimal manual operation, thanks to our sophisticated control systems, according to our customers, our plants prove to reduce 32% operation costs and labor costs.

-32%

OPERATION COSTS

Our mining crusher plant is widely used for crushing and screening materials for mining, construction, etc. We provide complete and tailor-made solutions for mining crushing works in huge bulk quantities for nearly any project, no matter small or large ones.

98%

APPLICATIONS

We can say that our mining crusher plant has 99% working performance thanks to our modern technology and the high-quality components that we use to create our mining crusher machines, which makes our crushing products superior to other competitors.

99%

WORK PERFORMANCE

Shunzhi Mining Crusher Plant Price List

| Types | Price Range |

| 5tph Mining Crushing Plant Price | $6,700 – $7,800 |

| 20tph Mining Crushing Plant Price | $9,500 – $11,000 |

| 50tph Mining Crushing Plant Price | $58,000 – $70,000 |

| 80tph Mining Crushing Plant Price | $65,000 – $76,000 |

| 100tph Mining Crushing Plant Price | $40,000 – $50,000 |

| 150tph Mining Crushing Plant Price | $105,000 – $220,000 |

| 200tph Mining Crushing Plant Price | $250,000 – $230,000 |

| 300tph Mining Crushing Plant Price | $170,000 – $182,000 |

| 600tph Mining Crushing Plant Price | $1,150,000 – $1,30,000 |

| 1000tph Mining Crushing Plant Price | $850,000 – $950,000 |

The mining crushing plant price is determined by the feeding capacity, machine types, and other equipment configurations. The capacity of the plant is a major factor that determines the price. The higher the capacity, the more expensive the cost will be.

The machine types also affect the price of mining crushing plants. Different types of machines used in different stages of the production lines will result in varying costs. Moreover, some other factors such as electricity consumption, labor costs, and other related expenses also play an important role in determining the overall cost of the mining crushing plant.

Additionally, choosing to install additional equipment such as dust removers, screens or conveyors can further increase the total cost.

Therefore, if you want to know the exact price of mining crusher plant, please contact us by clicking the button below, tell us your requirement and we will offer customized solutions and quote for you.

Types of Mining Crushing Plant for Sale

Shunzhi mining crusher plant has high safety standards and is equipped with safety features to protect the workers against any potential hazards. The low noise emissions ensure that the plant can be used in urban areas without causing any disruption. Additionally, it is easy to transport and move around on construction sites.

There are various capacities of mining crusher plants for sale and the plants are highly customizable and can be tailored according to the individual requirements of the customer.

Check Your Needed Mining Production Machines By Clicking the Capacities Below:

10-20 TPH / 30-50 TPH / 100-120 TPH / 150 TPH / 200 TPH / 250-300 TPH / 500-600 TPH / 1000 TPH

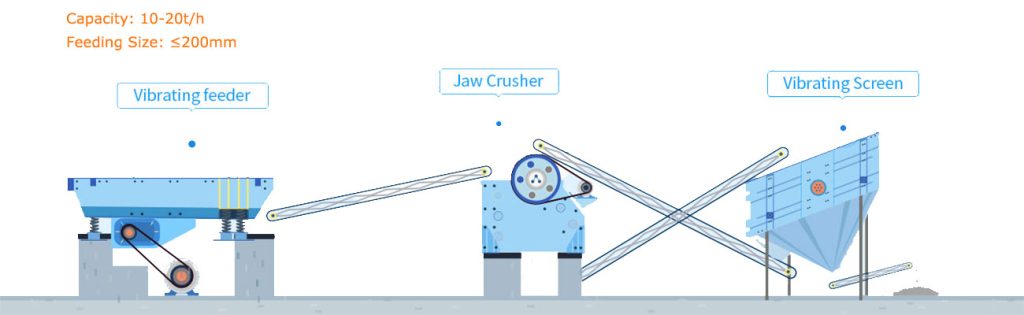

Small (10-20 TPH) Mining Crusher Plant

Capacity: 10 TPH – 20 TPH

Estimated Price Range: $6,700 – $7,800

| Feeding size | <200mm |

| Type of production line | Stationary Type |

| Floor area | 2700 sq ft |

| Types of finished products | 1 |

| Finished product specifications | 0-24mm |

Components of 10-20 TPH Small Mining Crusher Machines

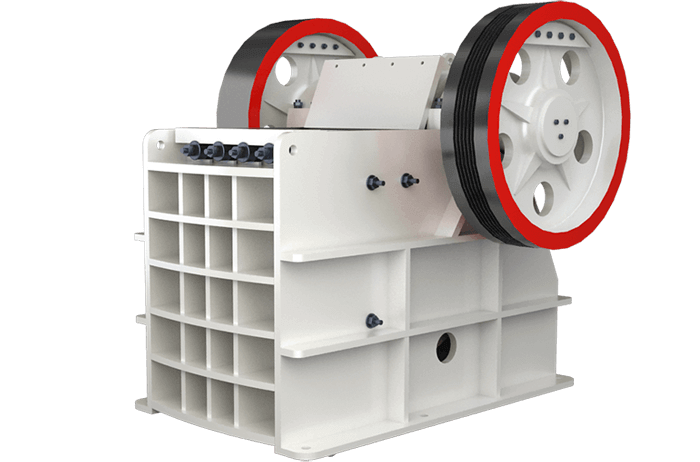

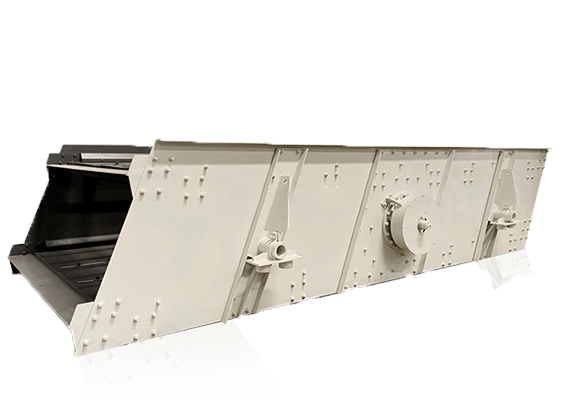

The 10-20 tph small mining crushing plant includes a vibrating feeder, a primary jaw crusher and a vibrating screen.

The small mining crusher plant is also often used for medium-sized crushing of ore and bulk materials, such as river pebbles, granite, basalt, iron ore, quartz stone, etc.

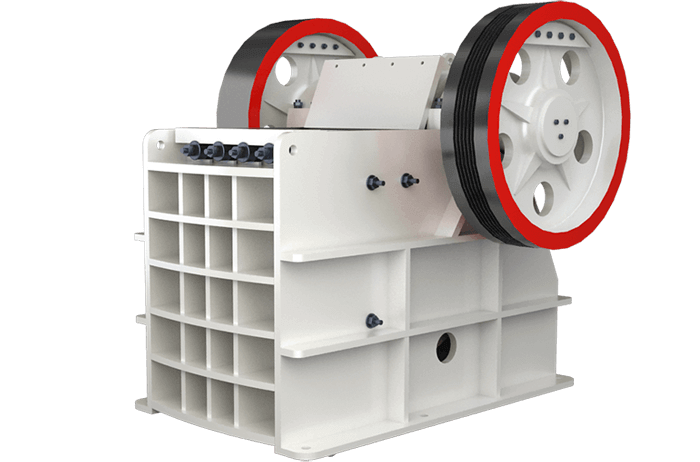

If you have a tight budget, a primary jaw crusher machine (PE250*400) is able to reduce the large size of raw materials into manageable sizes.

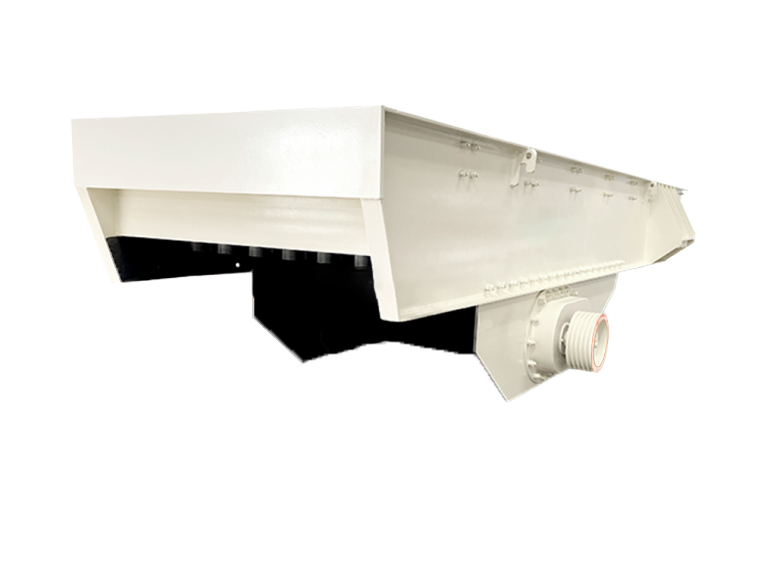

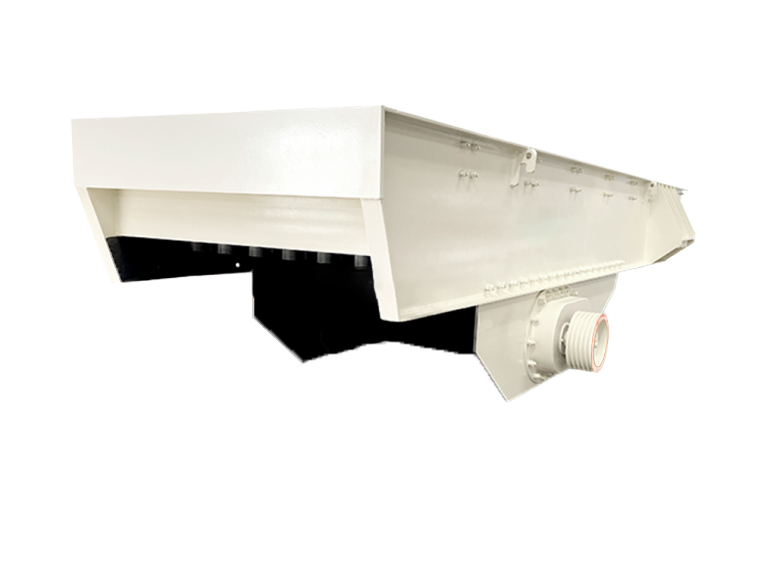

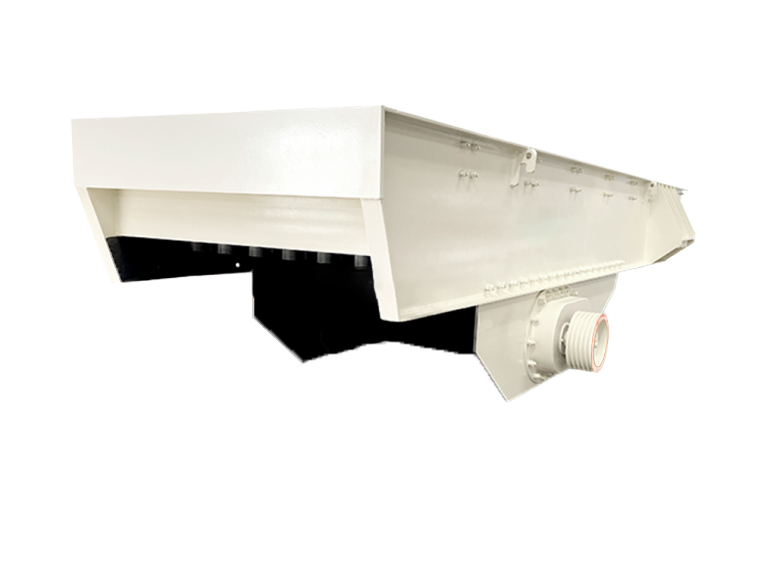

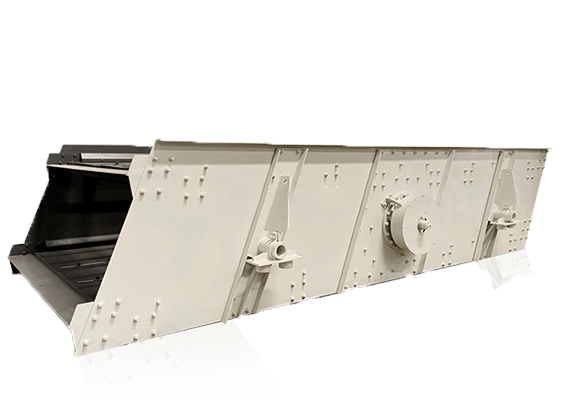

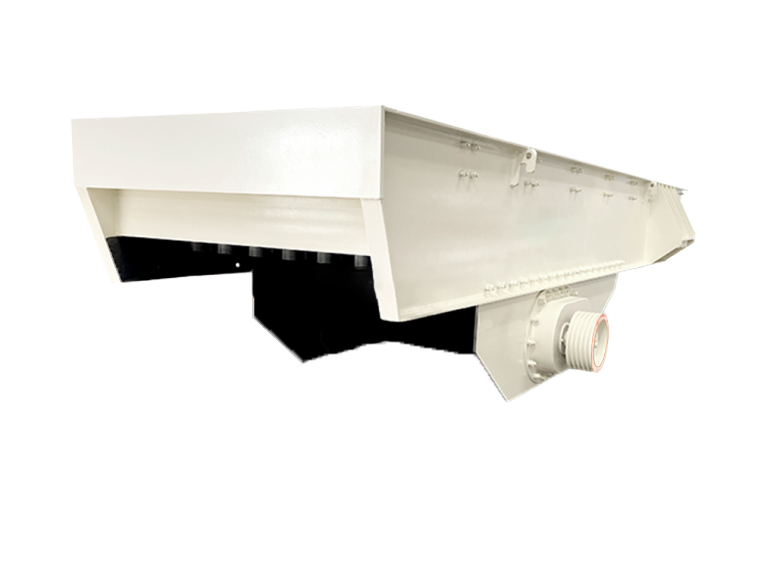

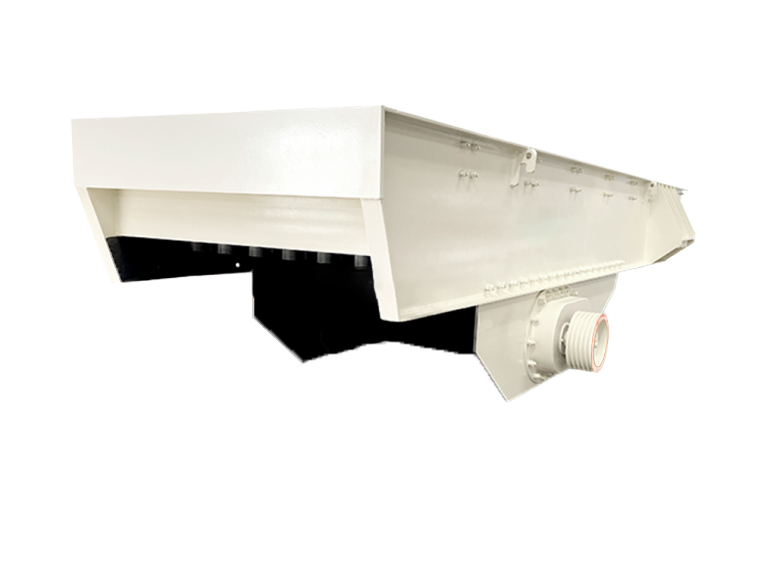

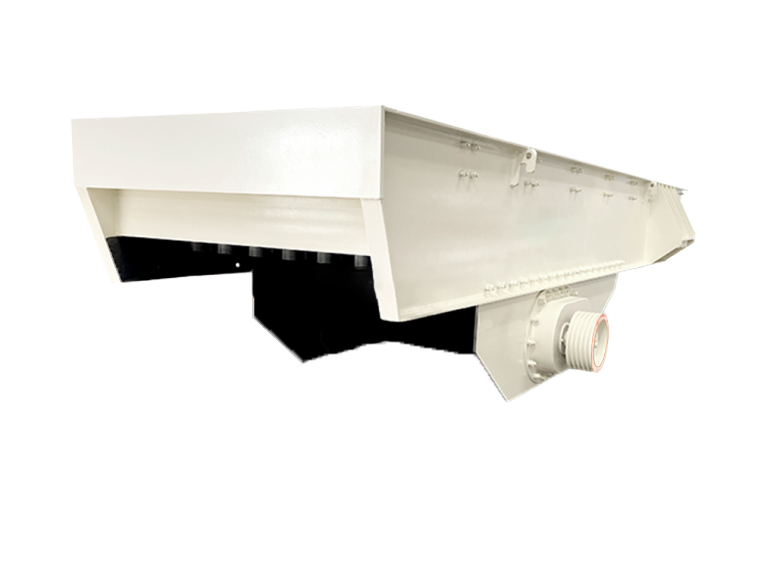

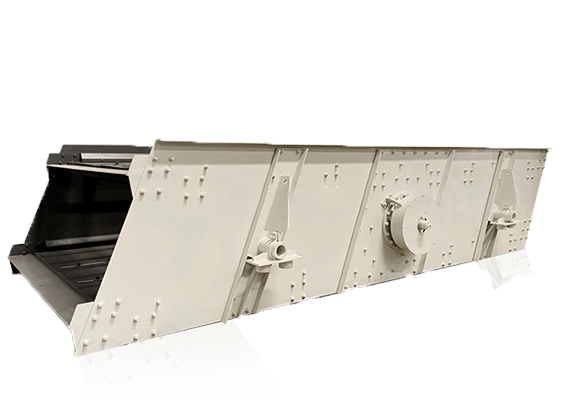

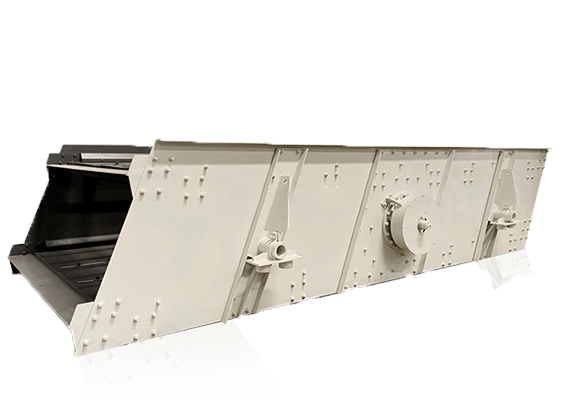

GZD750x2500 Vibrating Feeder

| Model | GZD750x2500 |

| Feeding Chute Size (mm) | 750×2500 |

| Max Feeding Size (mm) | 300 |

| Capacity (t/h) | 50-80 |

| Motor Power (kW) | 3 |

| Weight (kg) | 1590 |

| Overall Dimension (mm) | 2580x1100x1400 |

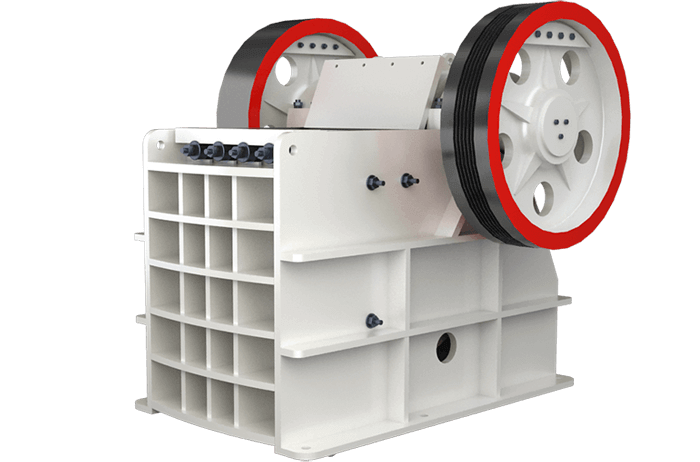

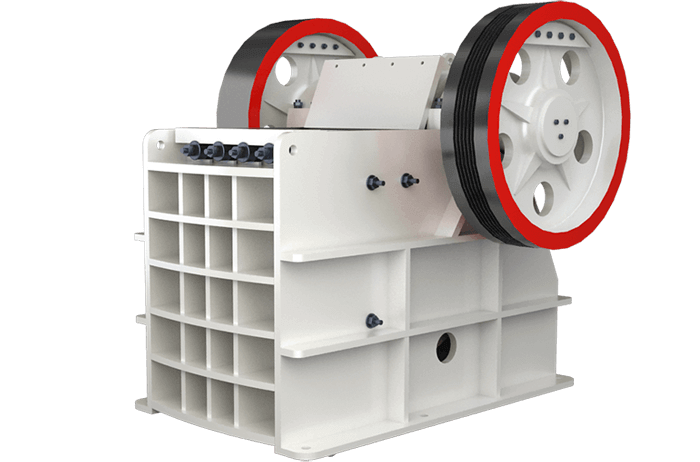

PE250*400 Jaw Crusher

| Model | PE250*400 |

| Feeding Opening (mm) | 250×400 |

| Max Feeding Size (mm) | 210 |

| Adjusting Rage of Discharge (mm) | 20-60 |

| Motor Power (kW) | 6P 15 |

| Weight (t) | 2.8 |

| Processing Capacity (t/h) | 5-21 |

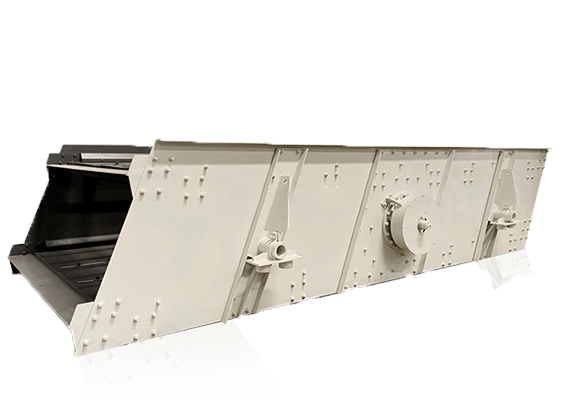

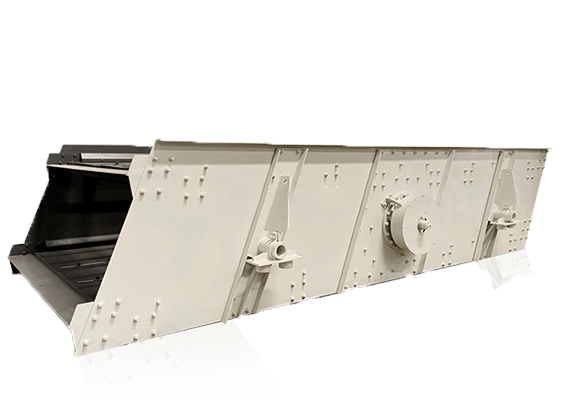

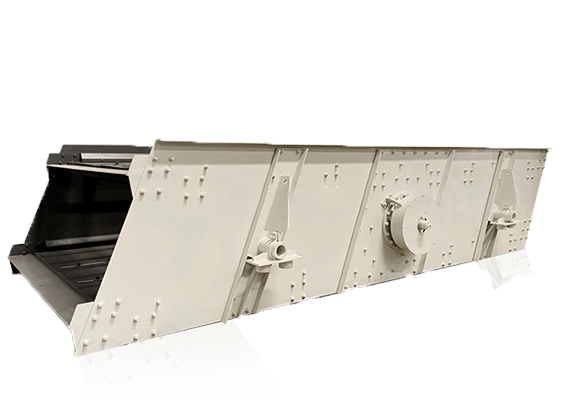

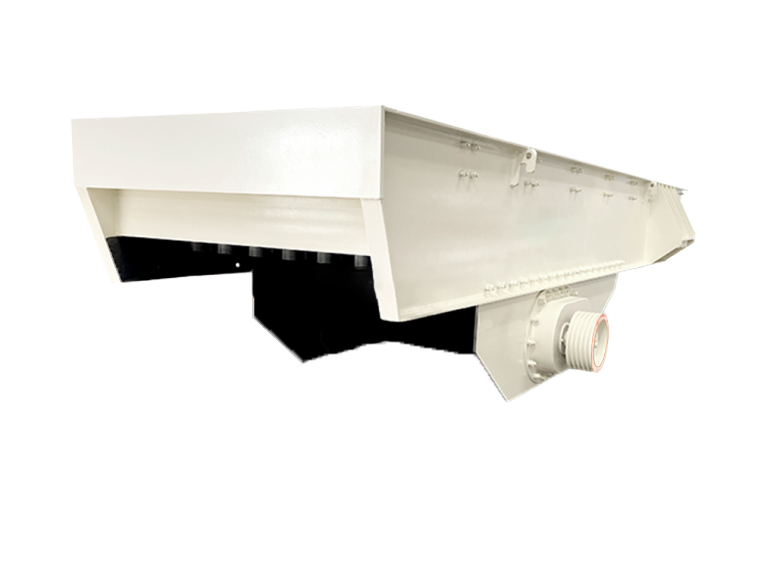

JC231 Vibrating Screen

| Model | JC231 |

| Feed Opening Size (mm) | 510×800 |

| Discharge Range (mm) | 40-150 |

| Capacity (t/h) | 50-250 |

| Motor Power (kW) | 55-75 |

| Weight (kg) | 9052 |

Parameters of 10-20 TPH Mining Production Line

| Model | Feeding Chute Size(mm) | Max Feeding Size(mm) | Capacity(t/h) | Motor Power(kW) | Weight(kg) | Overall Dimension(mm) |

| GZD750x2500 Vibrating Feeder | 750×2500 | 300 | 50-80 | 3 | 1590 | 2580x1100x1400 |

| PE250x400 Jaw Crusher | 250×400 | 210 | 5-21 | 6P 15 | 280 | / |

| JC231 Vibrating Screen | 510×800 | / | 50-250 | 55-75 | 9052 | / |

30-50 TPH Mining Crusher Plant

Capacity: 30TPH – 50 TPH

Estimated Price Range: $58,000 – $70,000

| Feeding size | ≤400mm |

| Type of production line | Stationary Type |

| Floor area | 3500 sq. ft. |

| Types of finished products | 3 |

| Finished product specifications | 0-5, 5-40, 40-70 mm |

Components of 30-50 TPH Aggregate Crusher Plant

Shunzhi 30-50 tph mining crushing plant includes best price vibrating feeder, a jaw crusher, an impact crusher machine and a vibrating screen.

This plant is suitable for mining processing or hard materials like ore. The primary jaw crusher reduces the material size to be fed into the impact crusher machine. The impact crusher crushes the material with its high-speed rotating hammers, and then the material is sent to the vibrating screen, which separates it into different sizes.

GZD750*2500 Vibrating Feeder

| Model | GZD750x2500 |

| Feeding Chute Size (mm) | 750×2500 |

| Max Feeding Size (mm) | 300 |

| Capacity (t/h) | 50-80 |

| Motor Power (kW) | 3 |

| Weight (kg) | 1590 |

| Overall Dimension (mm) | 2580x1100x1400 |

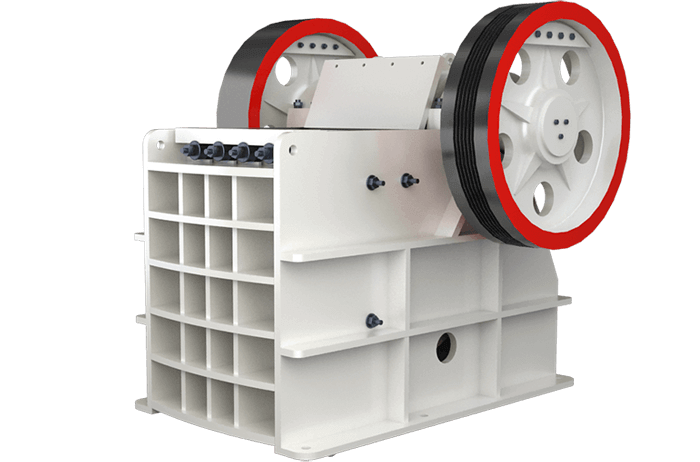

PE400*600 Jaw Crusher

| Model | PE400*600 |

| Feeding Chute Size (mm) | 400×600 |

| Max Feeding Size (mm) | 340 |

| Capacity (t/h) | 16-64 |

| Motor Power (kW) | 6P 30 |

| Weight (kg) | 1200 |

| Adjusting Range of Discharge (mm) | 40-100 |

PF1010 Impact Crusher

| Model | PF1010 |

| Feeding Chute Size (mm) | 1000×1050 |

| Max Feeding Size (mm) | 350 |

| Capacity (t/h) | 50-90 |

| Motor Power (kW) | 4P 45-55 |

| Weight (kg) | 1500 |

| Overall Dimension (mm) | 2370x1700x2390 |

JC231 Vibrating Screen

| Model | JC231 |

| Feed Opening Size (mm) | 510×800 |

| Discharge Range (mm) | 40-150 |

| Capacity (t/h) | 50-250 |

| Motor Power (kW) | 55-75 |

| Weight (kg) | 9052 |

Parameters of 30-50 TPH Mining Production Line

| Model | Feeding Chute Size(mm) | Max Feeding Size(mm) | Capacity(t/h) | Motor Power(kW) | Weight(kg) | Overall Dimension(mm) |

| GZD750x2500 Vibrating Feeder | 750×2500 | 300 | 50-80 | 3 | 1590 | 2580x1100x1400 |

| PE400*600 Jaw Crusher | 400×600 | 340 | 16-64 | 6P 30 | 700 | / |

| PF1010 Impact Crusher | 400*1080 | 350 | 50-90 | 4P 45-55 | 1500 | 2370x1700x2390 |

| JC231 Vibrating Screen | 510×800 | / | 50-250 | 55-75 | 9052 | / |

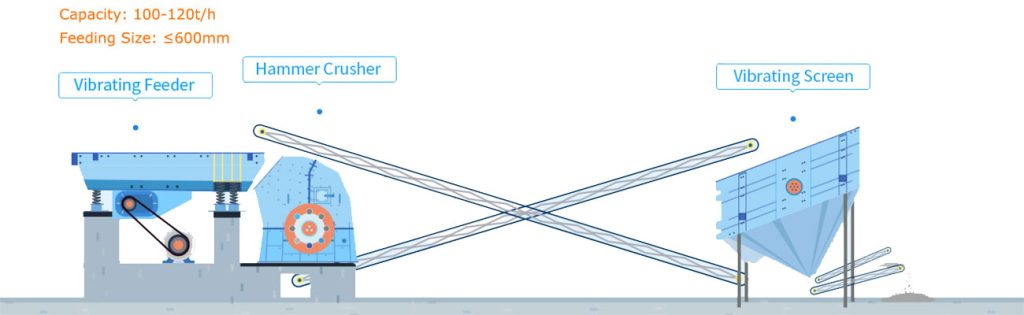

100-120 TPH Mining Crusher Plant

Capacity: 100TPH -120TPH

Estimated Price Range: $40,000 – $50,000

| Feeding size | ≤600mm |

| Type of production line | Stationary Type |

| Floor area | 5000 sq. ft. |

| Types of finished products | 2 |

| Finished product specifications | 0-5, 5-10 mm |

Components of 100-120 TPH Mining Crusher Plant

Shunzhi 100-120 tph mining crushing plant consists of a vibrating feeder, a heavy hammer crusher and a vibrating screen.

After feeding your raw materials, the heavy hammer crusher crushes the material with a powerful combination of hammer and anvil. The crushed materials are then transported to a vibrating screen where they are separated into different sizes of finished materials.

GZD850x3000 Vibrating Feeder

| Model | GZD850x3000 |

| Feeding Chute Size (mm) | 850×3000 |

| Max Feeding Size (mm) | 400 |

| Capacity (t/h) | 80-120 |

| Motor Power (kW) | 7.5 |

| Weight (kg) | 3895 |

| Overall Dimension (mm) | 3110x1800x1600 |

PCZ1308 Heavy Hammer Crusher

| Model | PCZ1308 |

| Feeding Chute Size (mm) | 870×780 |

| Max Feeding Size (mm) | 380 |

| Capacity (t/h) | 60-160 |

| Motor Power (kW) | 132 |

| Rotor Diameter*length (kg) | 1530×790 |

| Overall Dimension (mm) | 2880x2130x2390 |

JC340 Vibrating Screen

| Model | JC340 |

| Feeding Chute Size (mm) | 600×1020 |

| Discharge Range (mm) | 60-175 |

| Capacity (t/h) | 85-300 |

| Motor Power (kW) | 75-90 |

| Weight (kg) | 16460 |

Parameters of 100-120 TPH Mining Production Line

| Model | Feeding Chute Size (mm) | Max Feeding Size (mm) | Capacity (t/h) | Motor Power (kW) | Weight (kg) | Overall Dimension (mm) |

| GZD850x3000 Vibrating Screen | 850×3000 | 400 | 80-120 | 7.5 | 3895 | 3110x1800x1600 |

| PCZ1308 Heavy Hammer Crusher | 870×780 | 380 | 60-160 | 132 | / | 2880x2130x2390 |

| JC340 Vibrating Screen | 600×1020 | / | 85-300 | 75-90 | 16460 | / |

150 TPH Mining Crusher Plant

Capacity: 150 TPH

Estimated Price Range: $105,000 – $220,000

| Feeding size | ≤500mm |

| Type of production line | Mobile Type |

| Floor area | 2500 sq. ft. |

| Types of finished products | 3 |

| Finished product specifications | 0-10, 10-20, 20-30 mm |

Components of 150 TPH Portable Mining Crusher Plant

Our 150 tph mining crusher plant is mainly mobile type, consisting of a mobile hydraulic cone crusher plant and a mobile jaw crusher plant.

Compared with stationary mining crushing plant, mobile portable crusher plant is flexible enough to use in nearly any complicated working sites and significantly saves working space. Materials will be sent to jaw crusher through feeder, after primary crushing, the material will then be transported to cone crusher.

SZYLY200 Mobile Hydraulic Cone Crusher

| Model | SZYLY200 |

| Vibrating Feeder Size (mm) | 1000×5500 |

| Max Feeding Size (mm) | 185 |

| Crusher Feed Inlet (mm) | 210 |

| Powertrain Engine (kW) | 264 |

| Weight (t) | 35/41 |

| Overall Dimension (mm) | 14500/16400×2700/3000×3500 |

SZEL106 Mobile Jaw Crusher

| Model | SZEL106 |

| Vibrating Feeder Wide Length (mm) | 1060×4200 |

| Max Feeding Size (mm) | 560 |

| Side Belt Conveyor Wide Length (mm) | 650×4000 |

| Crusher Feed Inlet (mm) | 1060×700 |

| Weight (kg) | 42,000 |

| Overall Dimension (mm) | 15100x2800x3500 |

Parameters of 150 TPH Mining Production Line

| Model | Maximum Feeding size (mm) | Feeding Height (mm) | Silo Volume (m ³) | Vibrating Feeder Size (mm) | Crusher Model | Weight (t) |

| SZYLY200 Mobile Hydraulic Cone Crusher | 185 | 2600 | 5 | 1000×5500 | HPM200 | 35/41 |

| SZEL106 Mobile Jaw Crusher | 560 | 4000 | 6.5 | 1060×4200 | PE750x1060 | 42 |

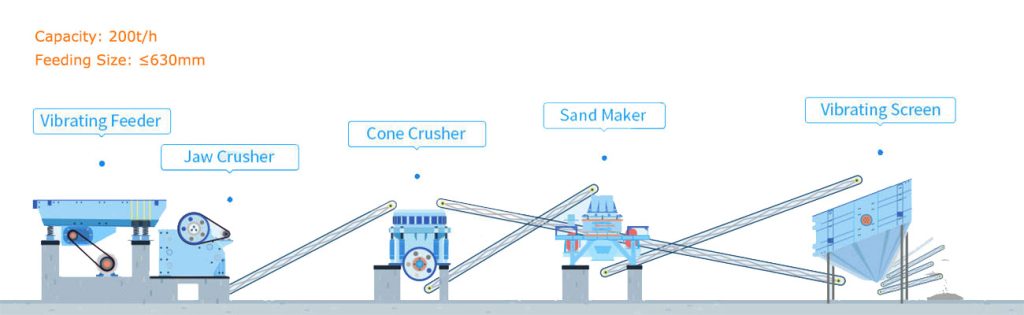

200 TPH Mining Crusher Plant

Capacity: 200 TPH

Estimated Price Range: $220,000 – $230,000

| Feeding size | ≤630mm |

| Type of production line | Stationary Type |

| Floor area | 5500 sq. ft. |

| Types of finished products | 4 |

| Finished product specifications | 0-5, 5-10, 10-20, 20-30 mm |

Components of 200 TPH Mining Crusher Plant

Shunzhi 200 tph mining crusher plant consists of vibrating feeder, 200 tph jaw crusher, 200 tph cone crusher, 200 tph vsi crusher machine and a vibrating screen.

Our 200 tph mining crusher plant can deals with hard rocks, those materials are transported to primary crushing process through vibrating feeder, and then broken into smaller size by jaw crusher, then comes the cone crusher, once the material is crushed small enough, it will then be sent into the vsi sand maker machine. The final crushing process is vibrating screen, fine sand will be produced through the whole crushing line.

GZD960*3800 Vibrating Feeder

| Model | GZD960x3800 |

| Feeding Chute Size (mm) | 960×3800 |

| Max Feeding Size (mm) | 500 |

| Capacity (t/h) | 120-210 |

| Motor Power (kW) | 11 |

| Weight (kg) | 4210 |

| Overall Dimension (mm) | 3850x1950x1630 |

PE750*1060 Jaw Crusher

| Model | PE750*1060 |

| Feeding Chute Size (mm) | 750×1060 |

| Max Feeding Size (mm) | 630 |

| Capacity (t/h) | 110-320 |

| Motor Power (kW) | 8P 110 |

| Weight (kg) | 29,000 |

| Adjusting Range of Discharge (mm) | 80-140 |

HPM200 Multi Hydraulic Cone Crusher

| Model | HPM200 |

| Feeding Chute Size (mm) | 185, 125, 95, 76, 54 |

| Max Feeding Size (mm) | 145, 100, 75, 60, 45 |

| Capacity (t/h) | 160-250, 145-250, 120-250, 108-210, 81-210 |

| Motor Power (kW) | 160 |

| Feeding Port Size (mm) | 185, 125, 95, 76, 54 |

| Discharge Opening Adjustment Range (mm) | 22, 18, 14, 12, 10 |

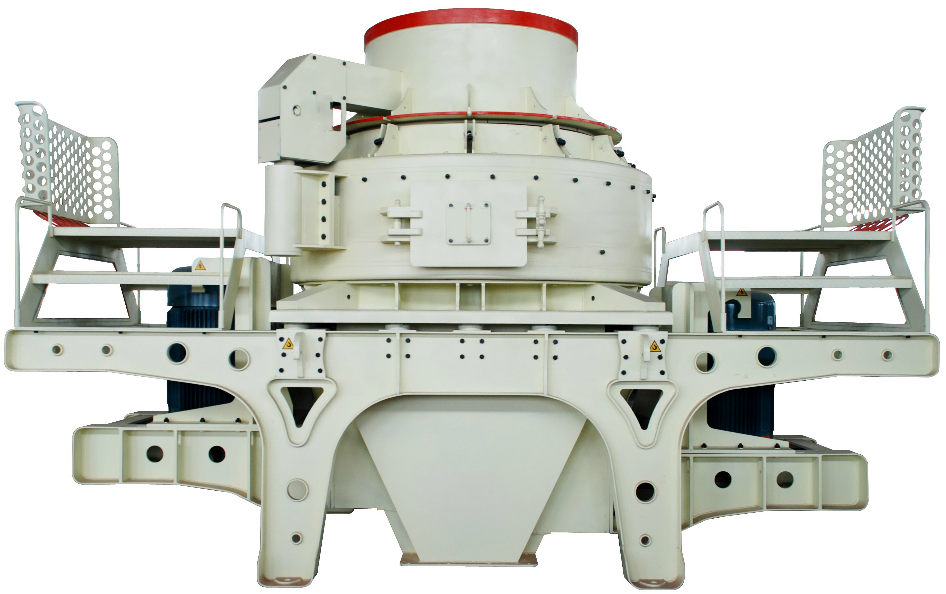

VSI5X7615 Sand Maker

| Model | PE750*1060 |

| Feeding Chute Size (mm) | 150-280, 70-140 |

| Max Feeding Size (mm) | 30, 35 |

| Rotation Speed (r/min) | 1700-1900 |

| Motor Power (kW) | 2×75 (100) |

| Weight (kg) | 8,600 |

| Overall Dimension (mm) | 4100×2330×2300 |

JC440 Vibrating Screen

| Model | JC440 |

| Feed Opening Size (mm) | 760×1020 |

| Discharge Range (mm) | 70-200 |

| Capacity (t/h) | 120-520 |

| Motor Power (kW) | 90-110 |

| Weight (kg) | 27,810 |

Parameters of 200 TPH Mining Production Line

| Model | Feeding Chute Size(mm) | Max Feeding Size(mm) | Capacity(t/h) | Motor Power(kW) | Weight(kg) | Overall Dimension(mm) |

| GZD960*3800 Vibrating Feeder | 960×3800 | 500 | 120-210 | 11 | 14210 | 3850x1950x1630 |

| PE750*1060 Jaw Crusher | 750×1060 | 630 | 110-320 | 8P 110 | 29,000 | / |

| HPM200 Multi Hydraulic Cone Crusher | 185, 125, 95, 76, 54 | 145, 100, 75, 60, 45 | 160-250, 145-250, 120-250, 108-210, 81-210 | 160 | / | / |

| VSI5X7615 Sand Maker | 150-280, 70-140 | 30, 35 | / | 2×75 (100) | 8,600 | 4100×2330×2300 |

| JC440 Vibrating Screen | 760×1020 | / | 120-520 | 90-110 | 27,810 | / |

250-300 TPH Mining Crusher Plant

Capacity: 250TPH – 300 TPH

Estimated Price Range: $170,000 – $182,000

| Feeding size | ≤630mm |

| Type of production line | Stationary Type |

| Floor area | 3500 sq. ft. |

| Types of finished products | 3 |

| Finished product specifications | 0-5, 5-40, 40-70 mm |

Components of 250-300 TPH Mining Crusher Plant

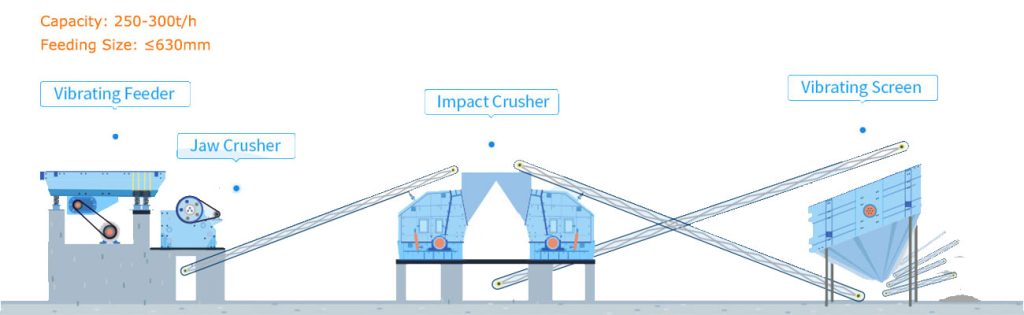

For soft raw material such as limestone, Shunzhi 250 tph mining crusher or 300 tph mining crusher plant is your perfect choice. The major machines involved in the whole crushing line include a vibrating feeder, a 300 tph jaw mining crusher, two sets of 250 impact crushers and a vibrating screen.

The primary jaw crusher is set to crush large materials into middle-size, then the impact crusher breaks them into smaller shapes. After the final sand screening, you will get your wanted size.

GZD1100*4900 Vibrating Feeder

| Model | GZD1100*4900 |

| Feeding Chute Size (mm) | 1100×4900 |

| Max Feeding Size (mm) | 650 |

| Capacity (t/h) | 220-460 |

| Motor Power (kW) | 15 |

| Weight (kg) | 5500 |

| Overall Dimension (mm) | 5200x2050x1700 |

PE900*1200 Jaw Crusher

| Model | PE900*1200 |

| Feeding Chute Size (mm) | 900×1200 |

| Max Feeding Size (mm) | 750 |

| Capacity (t/h) | 220-380 |

| Motor Power (kW) | 8P 160 |

| Weight (kg) | 52,000 |

| Adjusting Range of Discharge (mm) | 95-165 |

PF1320 Impact Crusher

| Model | PF1320 |

| Feeding Chute Size (mm) | 993×2000 |

| Max Feeding Size (mm) | 500 |

| Capacity (t/h) | 140-380 |

| Motor Power (kW) | 6P 250 |

| Weight (kg) | 34,000 |

| Overall Dimension (mm) | 3220x3100x3120 |

JC443 Vibrating Screen

| Model | JC443 |

| Feed Opening Size (mm) | 850×1100 |

| Discharge Range (mm) | 80-215 |

| Capacity (t/h) | 170-625 |

| Motor Power (kW) | 110-160 |

| Weight (kg) | 34,722 |

Parameters of 250-300 TPH Mining Production Line

| Model | Feeding Chute Size(mm) | Max Feeding Size(mm) | Capacity(t/h) | Motor Power(kW) | Weight(kg) | Overall Dimension(mm) |

| GZD1100*4900 Vibrating Feeder | 1100×4900 | 650 | 220-460 | 15 | 5500 | 5200x2050x1700 |

| PE900*1200 Jaw Crusher | 900×1200 | 750 | 220-380 | 8P 160 | 52,000 | / |

| PF1320 Impact Crusher | 993×2000 | 500 | 140-380 | 6P 250 | 34,000 | 3220x3100x3120 |

| JC443 Vibrating Screen | 850×1100 | / | 170-625 | 110-160 | 34,722 | / |

500-600 TPH Mining Crusher Plant

Capacity: 500TPH – 600 TPH

Estimated Price Range: $58,000 – $70,000

| Feeding size | ≤1000mm |

| Type of production line | Stationary Type |

| Floor area | 6500 sq. ft. |

| Types of finished products | 4 |

| Finished product specifications | 0-5, 5-10, 10-20, 20-30 mm |

Components of 500-600 TPH Mining Crusher Plant

If you want a mining crusher plant with 500-600 tph capacity, we would equip a vibrating feeder, 500/600 tph jaw crusher, two sets of single cylinder cone crushers, and 4 sets of vibrating screens.

This plant is perfect for crushing hard materials like granite. Through primary crushing and secondary crushing, the crushed materials will be sent to vibrating screen for screening. Our machines are all in delicate design to guarantee efficient working performance and quality output.

GZD1500*6000 Vibrating Feeder

| Model | GZD1500*6000 |

| Feeding Chute Size (mm) | 1500×6000 |

| Max Feeding Size (mm) | 950 |

| Capacity (t/h) | 500-850 |

| Motor Power (kW) | 30 |

| Weight (kg) | 9970 |

| Overall Dimension (mm) | 6160x2918x2292 |

PE1200*1500 Jaw Crusher

| Model | PE1200*1500 |

| Feeding Chute Size (mm) | 1200×1500 |

| Max Feeding Size (mm) | 1020 |

| Capacity (t/h) | 400-800 |

| Motor Power (kW) | 6P 160-240 |

| Weight (kg) | 100,900 |

| Adjusting Range of Discharge (mm) | 40-100 |

SC315 Single Cylinder Cone Crusher

| Model | SC315 |

| Feeding Chute Size (mm) | 275, 215, 175, 85 |

| Max Feeding Size (mm) | 220, 170, 170, 70 |

| Capacity (t/h) | 177-662, 209-643, 162-552, 175-325 |

| Motor Power (kW) | 315 |

| Minimum Discharge Opening Size (mm) | 32, 29, 29, 19 |

| Cavity Type | F1, F2, F3, F4 |

JC663 Vibrating Screen

| Model | JC663 |

| Feed Opening Size (mm) | 1200×1600 |

| Discharge Range (mm) | 150-350 |

| Capacity (t/h) | 500-1450 |

| Motor Power (kW) | 220-250 |

| Weight (kg) | 90,789 |

Parameters of 500-600 TPH Mining Production Line

| Model | Feeding Chute Size(mm) | Max Feeding Size(mm) | Capacity(t/h) | Motor Power(kW) | Weight(kg) | Overall Dimension(mm) |

| GZD1500*6000 Vibrating Feeder | 1500×6000 | 950 | 500-850 | 30 | 9970 | 6160x2918x2292 |

| PE1200*1500 Jaw Crusher | 1200×1500 | 1020 | 400-800 | 6P 160-240 | 100,900 | / |

| SC315 Single Cylinder Cone Crusher | 275, 215, 175, 85 | 220, 170, 170, 70 | 177-662, 209-643, 162-552, 175-325 | 315 | / | / |

| JC663 Vibrating Screen | 1200×1600 | / | 500-1450 | 220-250 | 90,789 | / |

1000 TPH Mining Crusher Plant

Capacity: 1000 TPH

Estimated Price Range: $850,000 – $950,000

| Feeding size | ≤800mm |

| Type of production line | Stationary Type |

| Floor area | 110,000 sq. ft. |

| Types of finished products | 4 |

| Finished product specifications | 0-5, 5-10, 10-20, 20-30 mm |

Components of 1000 TPH Mining Crusher Plant

Shunzhi 1000 tph mining crusher plant is normally a customized crushing line, the normal crushing plant machines include a vibrating feeder, a 1000 tph jaw crusher, an intermediate silo, two sets of impact crusher and a set of vibrating screen.

This plant is also suitable for processing super hard materials like bluestone. The price of 1000 tph mining crusher plant is determined by machine models, and if you want a 1000 tph mining crusher plant, please contact us and tell us all your requirements, we will give detailed solutions based on your needs.

GZD1500*6000 Vibrating Feeder

| Model | GZD1500*6000 |

| Feeding Chute Size (mm) | 1500×6000 |

| Max Feeding Size (mm) | 950 |

| Capacity (t/h) | 500-850 |

| Motor Power (kW) | 30 |

| Weight (kg) | 9970 |

| Overall Dimension (mm) | 6160x2918x2292 |

PE1500*1800 Jaw Crusher

| Model | PE1500*1800 |

| Feeding Chute Size (mm) | 1500×1800 |

| Max Feeding Size (mm) | 1200 |

| Capacity (t/h) | 500-1000 |

| Motor Power (kW) | 8P 335 |

| Weight (kg) | 139,000 |

| Adjusting Range of Discharge (mm) | 220-350 |

PF1820 Impact Crusher

| Model | PF1820 |

| Feeding Chute Size (mm) | 1260×2040 |

| Max Feeding Size (mm) | 800 |

| Capacity (t/h) | 400-800 |

| Motor Power (kW) | 4P 630-710 |

| Weight (kg) | 83,200 |

| Overall Dimension (mm) | 4400x3866x4009 |

JC983 Vibrating Screen

| Model | JC983 |

| Feed Opening Size (mm) | 1800×2100 |

| Discharge Range (mm) | 175-350 |

| Capacity (t/h) | 700-2100 |

| Motor Power (kW) | 355-450 |

| Weight (kg) | 180,000 |

Parameters of 1000 TPH Mining Production Line

| Model | Feeding Chute Size(mm) | Max Feeding Size(mm) | Capacity(t/h) | Motor Power(kW) | Weight(kg) | Overall Dimension(mm) |

| GZD1500*6000 Vibrating Feeder | 1500×6000 | 950 | 500-850 | 30 | 9970 | 6160x2918x2292 |

| PE1500*1800 Jaw Crusher | 1500×1800 | 1200 | 500-1000 | 8P 335 | 139,000 | / |

| PF1820 Impact Crusher | 1260×2040 | 800 | 400-800 | 4P 630-710 | 83,200 | 4400x3866x4009 |

| JC983 Vibrating Screen | 1800×2100 | / | 700-2100 | 355-450 | 180,000 | / |

Global Cases

20tph Mini Mining Crusher Works in Tunisia

Recently, a customer from Tunisia purchased a Shunzhi’s crusher machine for his mining business. He reported that the support from Shunzhi’s technology team was unparalleled. “When they encountered a slight technical hiccup, Shunzhi’s 24/7 support team was just a phone call away,” the customer said.

50tph Small Mining Crusher Plant Sent to Indonesia

Our customer from Indonesia said that the maintenance and installation are easy to understand, and all the staffs were helpful in providing a suitable solution for his needs. Customers also praised how quickly their orders were processed, and the low cost of spare parts.

100tph Mobile Mining Crusher Plant Sent to Zambia

A customer from Zambia praised Shunzhi’s plant for the educational support they provided. “The team gave accessible, comprehensive guidance for setting up and operating the crusher machine,” He said the step-by-step install guidance helped them with a strong start.

Working Process of Mining Crushing Plant

01

Primary crushing.

Firstly, the raw materials are sent to the jaw crusher for primary crushing. The finished products of this stage will be transported to the next process by belt conveyor.

02

Secondary crushing.

The materials will be crushed in a secondary crushing process such as an impact crusher or cone crusher. This step is followed by a screening process to separate the crushed materials into various sizes.

03

Sand washing.

The qualified material will be sent to a final product process such as sand making or washing plant for further processing. After this step, the end products are ready for usage and sale.

04

Transporting.

The last stage is to collect and transfer all the processed materials to the final destination. The transportation of raw materials and finished products may be carried out by truck, ship, train, or other suitable means.

The process can be adjusted according to the requirements of different customers and specific projects. In addition, some mining crushing plants are equipped with dust removal facilities to reduce environmental pollution.

These are the general steps involved in the mining crushing process. The specific details may depend on the project and local regulations. Tell us your requirement and we will offer tailor-made solutions based on your needs.

What Do Customers Talk About Us?

We were looking to upgrade our old mining crushing equipment and Shunzhi’s sales team took the time to assess my specific needs and recommend the perfect rock crusher model. Installation was quick and their training ensured my team could operate the new machine safely and properly.

– Diego Alejandro Anino Tupas

We’ve purchased mining crushers and crusher plants from Shunzhi over the years. They’ve always been attentive during the sales process and made sure we got the right equipment. My operators find their machines reliable and easy to use. Their customer service team is very helpful.

– Carlos Alberto Dimaunahan Osorio

Featured Products

Shunzhi Hammer Crusher

Shunzhi hammer crusher is suitable for crushing hard and medium hard materials in many industrial departments such as cement, chemistry, power station and metallurgy. The working principle is…