Роторная дробилка с вертикальным валом Shunzhi

Ударная дробилка с вертикальным валом (VSI) Shunzhi повышает эффективность работы до примерно 56% и при этом обеспечивает отличную кубическую форму частиц, что помогает сократить 25% ненужные расходы для всего проекта.

Наша машина - это высокоэнергетическое и малопотребляющее устройство, которое может быть использовано для измельчения руды в гравий. Этот тип машины доказал свою эффективность в различных других видах дробильного оборудования, что делает его незаменимой деталью для тех, кто ищет качественные материалы из своего сырья!

VSI дробилки для продажи

Высокая производительность дробилки Shunzhi vsi - Ударная дробилка с вертикальным валом и мобильные дробильные установки VSI в большом количестве на складе!

Размер корма: 0-60 мм

*Примечание: может быть изготовлен на заказ.

Вместимость: 60-750 т/ч

*Примечание: может быть изготовлен на заказ.

Применяемые материалы:

Подходит для дробления булыжника, базальта, гранита, железной руды, медной руды, цемента, искусственного песка, флюорита, известняка.

Применимые области:

Широко используется в формировании агрегатов, машинном производстве песка, строительных материалов, горнодобывающей, химической, металлургической, дорожной, водоохранной и других отраслях промышленности.

Типы роторных дробилок с вертикальным валом для продажи

Ударные дробилки с вертикальным валом, или дробилки vsi, - это тип дробилок, в которых для создания интенсивной силы столкновения используется технология высокоскоростного вращения ротора и крыльчатки. Это универсальное оборудование может использоваться во многих отраслях промышленности для решения различных задач.

Однако есть три основных типа дробилок VSI для продажи в Шуньчжи: роторная дробилка с вертикальным валом, мобильная дробильная станция VSI и гусеничная мобильная дробильная станция VSI. Вот краткий обзор каждого типа, чтобы помочь вам выбрать, какой из них подходит для вашего бизнеса.

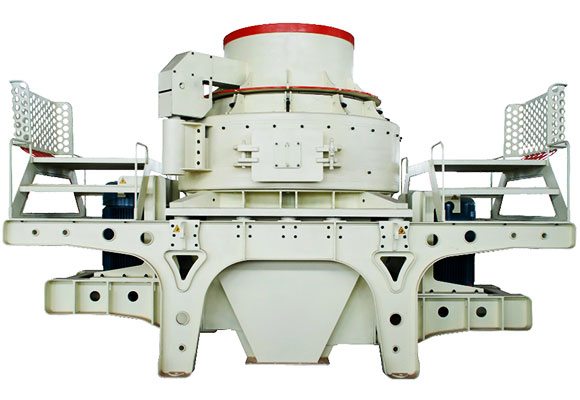

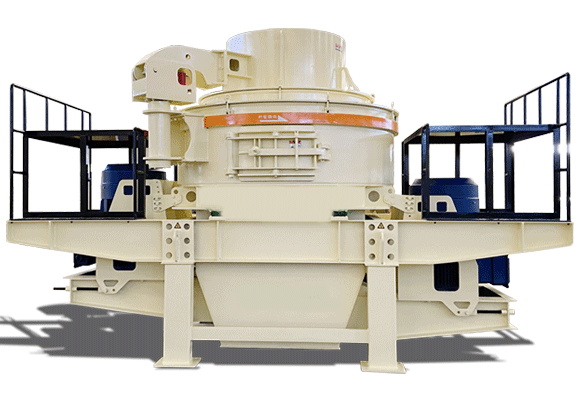

Ударная дробилка с вертикальным валом (VSI)

Роторная дробилка с вертикальным валом является одним из видов пескоделательной машины, которая широко используется в процессе производства шоссе, скоростных дорог, гравия и бетоносмесительных станций.

Он подходит для дробления материалов средней и выше твердости, таких как железная руда, руда цветных металлов, корунд, боксит, кварцевый песок, коричневый оксид алюминия, перлит, базальт и т.д.

| Модель | VSI5X7615 ~ VSI5X1145 |

| Пропускная способность (т/ч) | 150~280, 500~640 |

| Габаритные размеры L×W×H (mm) | 4100×2330×2300, 5000×2790×3320 |

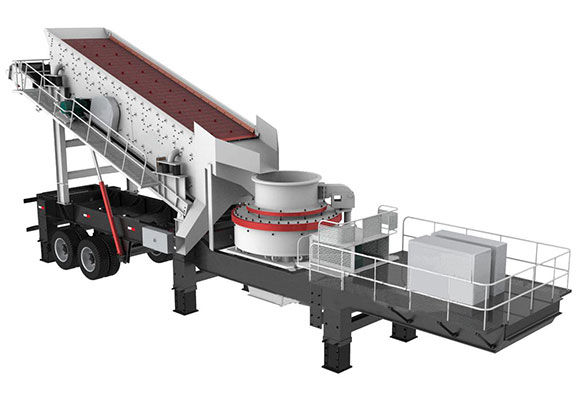

Мобильная дробильная установка VSI

Мобильная дробильная станция VSI - это полностью оборудованная дробильная установка, в которой используются дробилки с вертикальным валом для производства высококачественных заполнителей и грунтовых материалов.

Эта мобильная дробильная станция может быть легко транспортирована на место и обеспечивает гибкость в плане расположения и планировки.

Дробилки VSI, используемые в этой мобильной дробильной станции, показали себя очень эффективными в производстве высококачественных заполнителей и материалов для основания.

| Модель | SZYY300 ~ SZYY750 |

| Общая мощность (кВт) | 268.5 ~ 441 |

| Производительность (т/ч) | 120-320 ~ 180-284 |

Differences Between VSI and Other Vertical/Horizontal Impact Crushers

When comparing Vertical Shaft Impact (VSI) crushers with other impact crushers, such as Horizontal Shaft Impact (HSI) crushers, several key differences emerge.

Design and Operation: VSI crushers utilize a high-speed rotor that propels particles into a crushing chamber, where they collide with other particles or anvil surfaces for size reduction. In contrast, HSI crushers have hammers fixed to a rotating shaft, which strike materials as they enter the crushing chamber, creating a more direct, impact-driven reduction.

Product Shape: VSI crushers are known for producing highly cubical-shaped aggregates due to their unique crushing process, making them ideal for applications where particle shape is crucial. HSI crushers, while effective, typically yield more elongated shapes.

Strengths:

- VSI Crushers: Superior granulation, reduced wear on components, and high throughput in scenarios requiring fine product sizes.

- HSI Crushers: Higher capacities and better suited for softer materials; they often offer greater flexibility in material size reduction.

Weaknesses:

- VSI Crushers: Generally more prone to wear and tear due to the high-speed impacts and may be less effective with harder, more abrasive materials.

- HSI Crushers: Limited in producing high-quality fine aggregates and producing more elongated shapes, which may not meet specific quality requirements.

Overall, the choice between VSI and other impact crushers depends on the application, desired product characteristics, and the material being processed.

Shunzhi Ударная дробилка с вертикальным валом (VSI) Прайс-лист

| Типы | Диапазон цен |

| Роторная дробилка с вертикальным валом | $14,000 – $70,000 |

| Мобильная дробильная установка VSI | $30,000 – $150,000 |

| Мобильная дробильная установка на гусеничном ходу VSI | $30,000 – $150,000 |

Цены на роторные дробилки с вертикальным валом в основном определяются типом и размером вашего проекта.

Чем больше вы знаете об этих машинах, а также о других факторах, таких как, например, стоимость или требования к доставке, тем лучше мы сможем помочь вам принять решение о том, какая машина будет работать лучше всего с учетом этих качеств!

Cost of Ownership and ROI Analysis of VSI Crushers

When considering the cost of ownership for a Vertical Shaft Impact (VSI) crusher, several factors come into play that influence the overall return on investment (ROI). The initial investment includes the purchase price, installation costs, and the necessary infrastructure to support operation. While VSI crushers may have a higher upfront cost compared to other types of crushers, their long-term benefits often justify the expense.

VSI crushers are designed for durability and longevity, typically exhibiting lower wear rates and maintenance requirements. This reliability translates to reduced operational downtime and lower maintenance costs over the equipment’s lifecycle. Additionally, their ability to produce high-quality, cubical-shaped aggregates enhances the end product’s market value, leading to higher selling prices.

In terms of productivity, VSI crushers offer efficient processing capabilities that can yield high output levels, maximizing throughput while minimizing operating costs. The versatility of these crushers allows for processing a variety of materials, including recycled content, which can further enhance profitability.

When analyzing ROI, it’s essential to consider not just the initial investment but also potential savings in maintenance, increased production capacity, and the ability to deliver superior products that meet high market demand. Ultimately, the strategic use of VSI crushers can result in a favorable cost-benefit scenario for operators in the aggregate industry.

Наши преимущества

Роторная дробилка с вертикальным валом Shunzhi является высокоэффективным экологически чистым дробильным оборудованием, самостоятельно разработанным нашей компанией. Приглашаем клиентов со всего мира посетить наш завод для дальнейших консультаций!

Наша роторная дробилка с вертикальным валом разработана с блестящим уровнем качества, чтобы обеспечить равномерный кубический размер частиц, а содержание игл и хлопьев чрезвычайно мало, поэтому она подходит для формирования заполнителя.

97%

РАВНОМЕРНЫЙ РАЗМЕР ЧАСТИЦ

Функции мелкого дробления и грубого измельчения на нашей дробилке VSI повышают эффективность работы примерно до 56%, а простая конструкция также снижает большое количество эксплуатационных расходов.

+56%

ЭФФЕКТИВНОСТЬ РАБОТЫ

Машина обладает высокой способностью проходить через неразрушенные материалы и меньше подвержена влиянию влажности материалов, что позволяет использовать ее в различных областях горнодобывающей промышленности и при строительстве автомобильных дорог.

79%

ПРИЛОЖЕНИЯ

Благодаря передовой технологии, а также надежным деталям, используемым в машине, мы уменьшаем загрязнение железом 30% и тем временем обеспечиваем насыпную плотность продукции, что позволяет снизить ненужные расходы 25%.

-30%

ЗАГРЯЗНЕНИЕ ОКРУЖАЮЩЕЙ СРЕДЫ ИРОНОМ

Role of VSI Crushers in Sustainable Practices

Vertical Shaft Impact (VSI) crushers play a significant role in promoting sustainable practices in the aggregate and construction industries. One of their key contributions to environmental sustainability is through enhanced recycling efficiencies. VSI crushers are highly effective in processing recycled materials, such as concrete and asphalt, allowing for the repurposing of waste into usable aggregates. This not only reduces the demand for virgin materials but also minimizes landfill accumulation, contributing to a circular economy.

Moreover, the design of VSI crushers allows for energy-efficient operation. They generally require less energy than traditional crushing methods, leading to lower greenhouse gas emissions during the production of aggregates. By optimizing the crushing process to produce high-quality outputs with minimal energy consumption, VSI technology supports both environmental and economic sustainability.

Additionally, the ability of VSI crushers to produce cubical particles improves the performance of concrete and asphalt mixtures, thereby extending the lifespan of infrastructure and reducing the frequency of repairs or replacements. Ultimately, employing VSI crushers aligns with sustainable development goals by minimizing environmental impact, promoting efficient resource use, and supporting recycling initiatives, which are vital for reducing the carbon footprint of construction activities.

Как дробилка с вертикальным валом (VSI) Shunzhi улучшает ваш бизнес?

Прочная и надежная конструкция

Разработанная со сварной рамой из углеродистой стали и хромированной железной загрузочной плитой, башмаками рабочего колеса и внешней загрузочной трубой, роторная дробилка с вертикальным валом Shunzhi отличается высокой прочностью и надежностью в работе.

Гибкий и регулируемый

Многочисленные модели мобильных роторных дробилок с вертикальным валом позволяют использовать их в любых сферах применения благодаря их супергибкости, а также изменять их конфигурацию в зависимости от ваших потребностей.

Широкий диапазон скоростей вращения ротора

Варьируя скорость вращения от 1700~1900 об/мин до 1100~1310 об/мин, наша машина обеспечивает точный контроль качества и градации продукта.

Большая производственная мощность

Максимальная пропускная способность центральной и кольцевой подачи достигает 500~640 т/ч, а пропускная способность центральной подачи - 250~360 т/ч, что позволяет широко использовать нашу машину в различных областях.

Working Principle of Vertical Shaft Impact Crusher

The working principle of a Vertical Shaft Impact (VSI) crusher revolves around the accelerated particles impacting against a material, usually rock, to achieve the desired size reduction and shaping. The core mechanism of a VSI crusher involves a high-speed rotor, which spins at high revolutions per minute (RPM).

Initially, the material is fed into the center of the rotor, where it is rapidly thrown outward by centrifugal force. As the particles leave the rotor, they impact against fixed anvils or other rock particles in the crushing chamber. This impact creates a high degree of fragmentation and shapes the material into cubical products, which is particularly beneficial in the production of high-quality aggregates.

The unique design of a VSI crusher allows for the control of product shape and size, making it versatile for various applications including sand making, and shaping of stone in gravel quarries. Additionally, the closed-circuit design often employed in VSI operations allows for the efficient recycling of material, thereby maximizing the use of resources. The ability to operate with low wear rates and reduced energy consumption further enhances the appeal of VSI technology in aggregate processing and other material production industries.

Глобальные случаи

VSI5X9532 VSI дробилка работает в Южной Африке

Поздравляем! Наша дробилка VSI5X9532 VSI помогла нашим клиентам завершить крупный проект по добыче полезных ископаемых, и ее высокие рабочие характеристики в очередной раз подтвердились.

VSI5X1145 VSI дробилка Отправлено в Кению

Другой комплект VSI5X1145 VSI дробилки был отправлен в Кению и начал работать в течение нескольких месяцев, согласно отзывам, они находятся в отличных рабочих условиях в настоящее время.

VSI5X7615 VSI дробилка отправлена в Нигерию

Центральная и кольцевая подача этой VSI5X7615 VSI дробилки составляет 150-280 т/ч, после отправки в Нигерию, эта машина играет важную роль в дроблении камня до сих пор.

Мобильная дробильная станция SZCLY800 VSI работает на Филиппинах

Мы очень рады, что наша мобильная дробильная станция VSI отлично работает на Филиппинах, клиенты хвалят, что наши машины очень гибкие и снижают эксплуатационные расходы для них.

Технические характеристики

| Модель | VSI5X7615 | VSI5X8522 | VSI5X9532 | VSI5X1145 |

| Центральная и кольцевая подача Пропускная способность (т/ч) | 150~280 | 240~380 | 350~540 | 500~640 |

| Центральная подача Пропускная способность (т/ч) | 70~140 | 120~190 | 180~280 | 250~360 |

| Мягкий материал Макс. Размер подачи (мм) | <35 | <40 | <45 | <50 |

| Твердый материал Макс. Размер подачи (мм) | <30 | <35 | <40 | <45 |

| Скорость вращения (об/мин) | 1700~1900 | 1500~1700 | 1300~1510 | 1100~1310 |

| Мощность двойного двигателя (кВт) | 2×75 (100) | 2×110 (150) | 2×160 (220) | 2×220 (300) |

| Габаритные размеры Д×Ш×Г (мм) | 4100×2330×2300 | 4140×2500×2700 | 4560×2600×2900 | 5000×2790×3320 |

| Вес (т) | 8.6 | 11.8 | 17.5 | 27.5 |

| Питание для двойного масляного насоса | 2×0.25(0.33) | 2×0.25(0.33) | 2×0.25(0.33) | 2×0.25(0.33) |

| Питание нагревателя масляного бака | 2 KW | 2 KW | 2 KW | 2 KW |

| Габаритные размеры Д×Ш×Г (мм) | 820×520×1270 | 820×520×1270 | 820×520×1270 | 820×520×1270 |

Что говорят о нас клиенты?

Если вы заказывали машину у Shunzhi, вы поймете мои чувства. Мы заказали у них машину vsi 2 года назад и так рады, что я уже вернул свои инвестиции.

- Трей Йосеф Манлапаз Панопио

Роторная дробилка с вертикальным валом, которую мы заказали, находится в идеальном рабочем состоянии, она действительно работает так, как рекламируется, мы будем сотрудничать с ними снова!

- Тито Дэвид Талатала Самонте

Часто задаваемые вопросы

Популярные товары

Молотковая дробилка Shunzhi

Молотковая дробилка Shunzhi подходит для дробления твердых и средне-твердых материалов во многих промышленных отраслях, таких как цемент, химия, электростанция и металлургия. Принцип работы...