Shunzhi Sand Crushing Plant

Shunzhi sand crushing plant is a cutting-edge facility that produces high-quality sand from waste materials. It’s environmentally friendly, cost-effective, and can be used in a variety of construction applications.

From stone to sand, our sand making plant or stone aggregate production line can produce high-quality artificial sand which is widely used in the construction industry.

Types of Sand Making Production Lines for Sale

Based on your output and raw materials demands, Shunzhi has three types of sand making plant, including a stone aggregate production line, a sand production line, and a construction waste crushing production line. The specific production line configuration can be customized and each fits multiple applications.

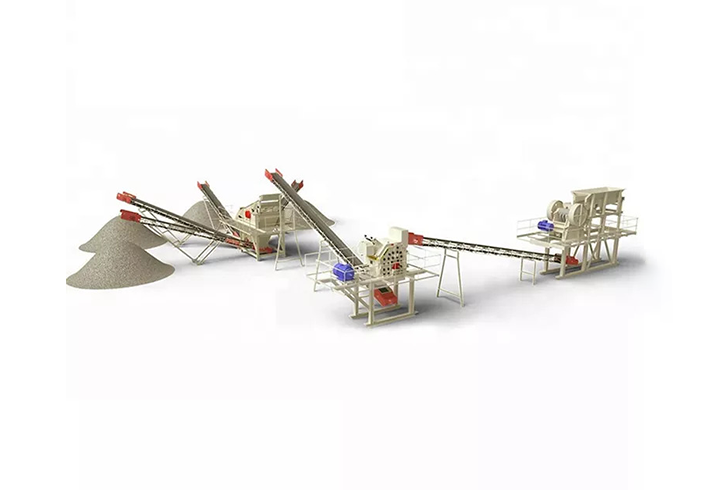

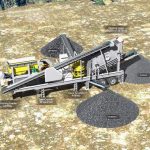

Stone Aggregate Production Line

A stone aggregate production line is a collection of machines used to crush, grind, and wash rocks into a suitable mixture for use in construction projects.

The production of raw materials for road construction and other projects often requires the use of specialized plants. These facilities are expensive to set up, but they produce large quantities with high yields that can meet any need you may have!

NOTE:

Specific production line configurations can be customized.

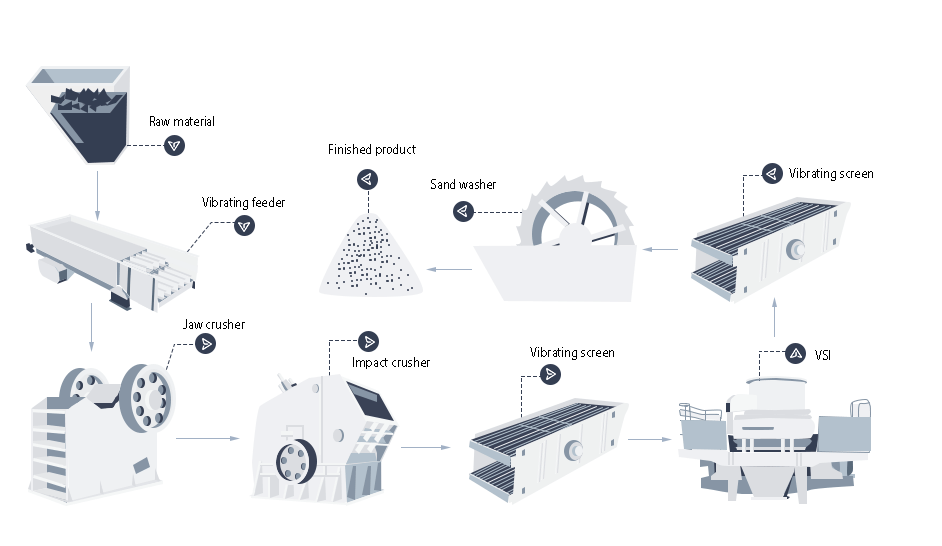

Sand Production Line

The sand production line is special equipment for the production of construction sand and stone. The sand making machine produced by our company can provide you with all-around technical support.

The whole line consists of a vibrating feeder, jaw crusher, impact crusher/cone crusher, sand making machine, vibrating screen, sand washing machine, conveyor, integrated electric control, and other equipment. According to specific requirements, we can combine different models together to meet your different needs.

NOTE:

The equipment configuration of the sand production line is mainly determined according to the customer’s specifications for the finished sand, the output and the type of stone.

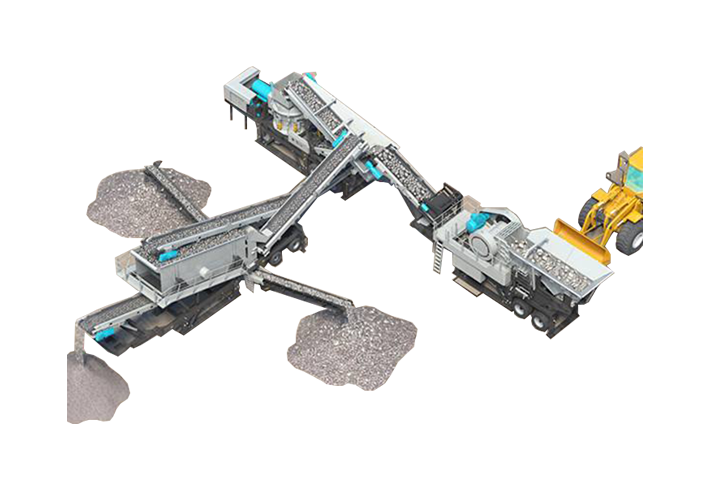

Construction Waste Crushing Production Line

Construction waste crushing production line is improved from the traditional crushing model of using jaw crusher and impact crusher, which not only saves a lot of infrastructure investment costs for customers, but also achieves good crushing effect, and finally realizes the comprehensive utilization of construction waste.

The major components include a mobile crushing station, feeder, jaw crusher, round vibrating screen, belt conveyor, etc.

NOTE:

The configuration depends on broken materials and can be customized.

Our Advantages

Our sand production line includes a sand production line, stone aggregate production line, and construction waste crusher, all of which are of brilliant quality level.

Different grades of sand are available depending on the size that is needed. From 50t/h – 500t/h, you can customize any range of finished product sizes based on your requirements.

50-500t/h

Configuration

Our machine’s routine inspections are simple and quick because the wearing parts use high-strength materials that last for a super long periods in service life spans compared with others.

-30%

maintenance costs

The high production efficiency and automation degree of our production line make it an excellent choice for large-scale mining operations, reducing a large number of operating costs.

-46%

Operation costs

The application range of our rock crushing machines in all production lines is wider than most otherson the market and applies to most of the construction and mining, highway applications.

All

Application available

Shunzhi Sand/Gravel Crushing Plant Price List

| Types | Price Range |

| Stone Aggregate Production Line | $10,000 – $200,000 |

| Sand Production Line | $30,000 – $150,000 |

| Construction Waste Crushing Production Line | $30,000 – $150,000 |

All the given prices are just referenced prices, the specific price is based on the required configuration. We can custom-make any type of sand-making machine or stone jaw crusher to meet your needs.

If you have questions about our available products, please do not hesitate and send us an email! We will show more detailed information such as videos for each device along with other helpful resources like screening machines available for purchase; no matter what decision fits best in terms of price range etc., we’re here ready to help guide you towards success.

Shunzhi Sand Making Plants Application

Shunzhi sand production plant has a wide range of applications in the construction industry. From road building to foundation laying, this equipment is essential in the production of artificial sand and other aggregates. It is mainly used for producing high quality construction sand, which can be blended with gravel or asphalt for the construction of highways, bridges and other infrastructure projects.

Generally speaking, our sand crushing plants can be used in industries like,

- Water conservancy and hydropower;

- Construction of tunnels, highways and railways;

- Real estate development, ports and airports;

- Engineering projects;

- Mining, metallurgy and chemical industries;

- Cement, concrete processing industries.

If you are in the construction industry and need high quality sand machines for your projects, please contact us today to learn more about our Shunzhi sand making plant. We can provide you with the best equipment for your needs and help you get the most out of your construction.

How Shunzhi Sand Making Lines Improve Your Business?

Advantages of Stone Aggregate Production Line

The high degree of automation

Our stone aggregate production line has a high degree automation design to reduce operator, low running costs, and stable operation.

Uniform particle size

Our machine guarantees uniform particle size output, which greatly reduces the phenomenon of uneven fineness when using other sand making machines. It also consumes less energy during production.

High Efficient

The machine in our company is equipped with advanced production technology and has high production efficiency. It can produce a large number of high-quality artificial sands at one time, and the output is very high.

Advantages of Sand Production Line

Simple production process

Our sand making machine has a simple production process, which can be roughly divided into three steps: material feeding, crushing, and sand making. The whole sand making process is simple, reasonable, and efficient, and it can be put into production quickly after being put into production.

Low failure rate

The sand making machine has a low failure rate and high output. It is generally used for the production of glass, ceramics, refractories, cement, and other products.

Intelligent control

With an intelligent control system, it can automatically adjust the speed according to the material characteristics and feed amount. And it is easy to operate and maintain, which greatly reduces maintenance costs.

Advantages of Construction Waste Crushing Production Line

Apply to a wide range of materials

The construction waste crushing production line has a wide application range and it can be applied to many fields such as building materials, metallurgy, the chemical industry, etc. It is suitable for the crushing of various ores and rocks with medium or above hardness.

Convenient operation

With Shunzhi construction waste crushing production line, the whole operating costs will be saved by around 30%. And fully automated control system keeps the output always at a good quality level.

High working efficiency

The multi-stage crushing technology uses a two-stage or three-stage crushing process to achieve high crushing efficiency.

Global Cases

Stone Crushing Plant Works in Kenya

Shunzhi stone crushing plant was transported to Kenya two months ago. Now it has been put into aggregate production and the customers said Shunzhi is reliable and worth trusting for high quality & professional service.

Sand Production Line Works in Malaysia

250t/h sand production line produced by Shunzhi was transported to Malaysia last year, and it is now still working in perfect quality level. Shunzhi has always adhered to the client-centric belief and welcomes your requirements or suggestions for our crushing plants. If you are interested, please feel free to contact us.

Construction Waste Crushing Plant Work in Tanzania

Shunzhi 200t/h mobile construction waste crusher plant was delivered to Tanzania in May 2019. because of the reasonable matching of different levels of crushing equipment and rigorous space-crossing layout, it has small floor space, high economic benefit, high-quality stone material, and low powder rate.

Sand Production Line Works in Morocco

Congratulations! One set of the sand production lines was sent to Morocco last month. Our stone crusher plant features a large crushing ratio, high productivity, and easy maintenance, which can bring great economic benefits to clients.

Components of Sand Crushing Plant

Sand crushing plant consists of a vibrating feeder, jaw crusher, vertical shaft impact crusher (sand making machine), vibrating screen, sand washing machine, belt conveyor,

and centrally electric controlling system, etc. the designed capacity can be customized based on your needs.

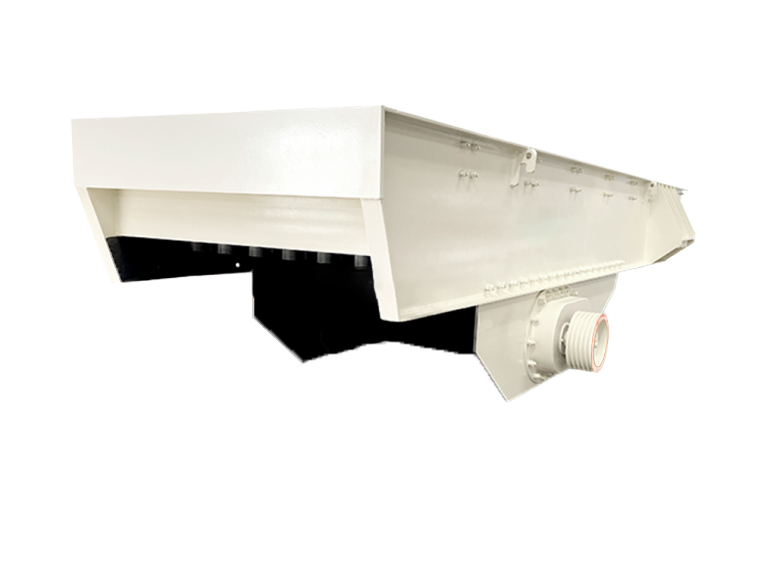

Vibrating Feeder

Vibrating feeder is widely used in metallurgy, coal, chemical industry, building materials, light industry, and other industries. In the crushing and screening production line, a vibrating feeder is used to evenly and continuously convey blocky or granular materials from the material receiving device to the jaw crusher for coarse crushing.

Stable and reliable vibrator.

Adjustable grid bar clearance.

A special grid bar design prevents material blockage.

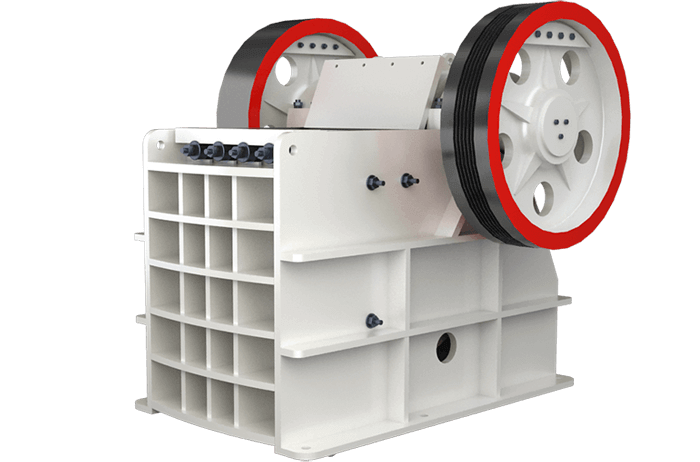

Jaw Crusher

A jaw crusher is used to crush stone or ore into small pieces in order to make them more manageable. It is mainly used in the primary and secondary crushing processes for mining and rock grinding.

Low noise and little dust.

Large crushing ratio and uniform product granularity.

Safe and reliable lubrication, simple to maintain design.

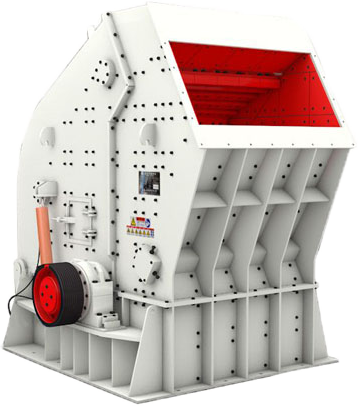

Impact Crusher

An impact crusher is generally used as a secondary crusher, and by changing the rotor and crushing cavity, it can also be used as a primary crusher according to the customer’s requirements.

Super effective in handling materials with large moisture content.

Applicable to a wider range of material hardness.

Small wearing parts, high metal utilization rate.

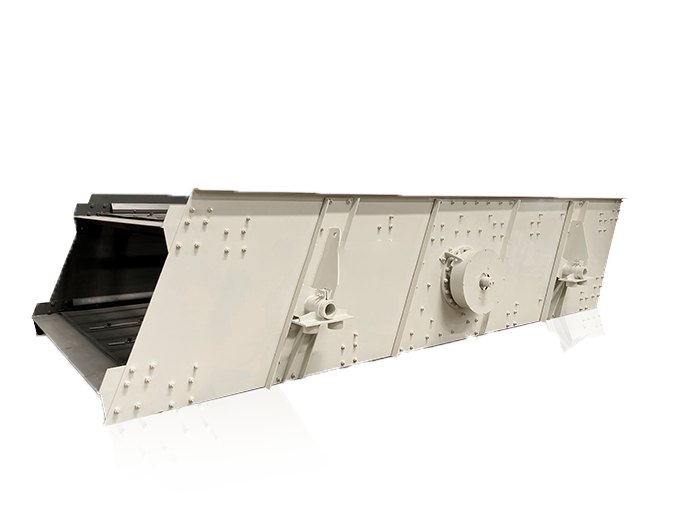

Vibrating Screen

The vibrating screen is driven by the vibrator on the side of the screen box. The centrifugal force generated by the rotation of the unbalanced weight on the vibration exciter makes the screen body periodically perform a circular, elliptical, or linear motion.

High screening frequency, small amplitude.

High efficiency and large capacity.

Low requirements for the moisture content of the material.

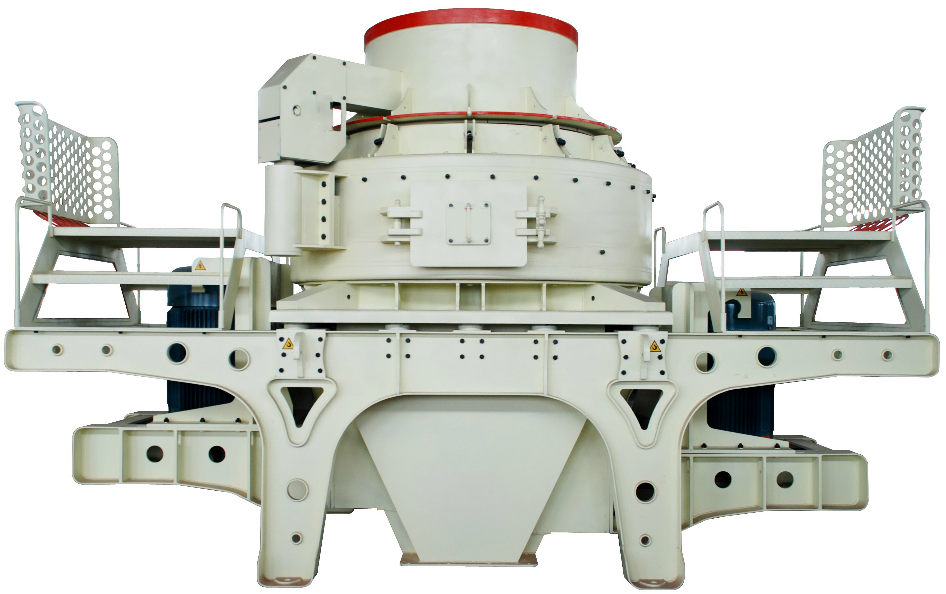

VSI Crusher

A vertical shaft impact crusher is known as sand making machine. It is an indispensable machine in sand making industry and it is also the most ideal truing machine for the mining and construction industries.

High crushing efficiency, with fine crushing and coarse grinding functions.

Has strong ability to pass through non broken materials.

High bulk density of products, small iron pollution.

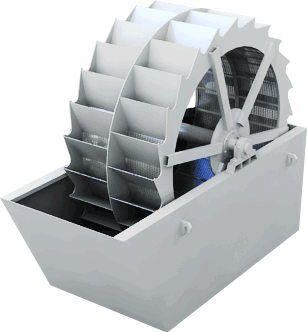

Sand Washer

The sand washer consists of a motor, a decelerator, a spiral conveyor, and a reducer. It is suitable for washing and drying all kinds of materials in construction, transportation, the chemical industry, etc.

Simple structure and stable operation.

Applicable to various working environments.

High washing efficiency to meet high-grade materials requirements.

Working Process of Sand Production Line

01

Stone crushing.

This step generally uses a jaw crusher or cone crusher. The stone that meets the particle size requirements will be sent to the next step, while the stone that does not meet the requirements will be returned to the crusher for re-crushing until it meets the particle size requirements.

02

Sand washing.

We use professional sand washing equipment to wash away the impurities that cover the surface of the sandstone.

03

Secondary screening.

In this step, we use a circular vibrating screen to screen out finished products that meet our requirements and return unfinished products to the previous link for re-crushing until they are of the required particle size.

Sand Making Machine Special Structure and Design

Shunzhi sand making machine, or named vertical shaft impact crusher is designed with a feed hopper, distributor, vortex crushing cavity, impeller, protecting plates, base, and transmission device.

Feed Hopper

The feed hopper is structured with an inlet chute and a rotary feeder with two different models. The raw material enters the hopper via gravity-fed, then transferred to the crusher.

Distributor

The distributor is used to distribute materials evenly over the crushing chamber and ensure a uniform product size. It is composed of multiple blades with adjustable gap and can be configured according to the material characteristics.

Vortex Crushing Cavity

The vortex crushing cavity is the core part of sand making machines. It is composed of impeller, air deflector, cone-shaped shell and other components. The crushing chamber is designed with a special shape that can increase the material throughput and reduce the wear of the parts.

Impeller

The impellers are the main parts of sand making machine. They are mainly composed of a single or double impeller and a spindle assembly. The number of blades can be adjusted according to the material properties.

Protecting Plates

The protecting plates are designed to protect the impeller and other parts from being damaged by the stones or other materials.

Shunzhi adopts an advanced design with protecting plates that can enlarge the lifespan, but most importantly, can reduce the material waste and improve the material utilization rate.

Base

The base is used to support and fix the whole sand making machine. It is designed with a large bearing capacity and strong stability to ensure the operation of the sand making machine.

Transmission Device

The transmission device is used to transmit the power from the motor to the impeller. Shunzhi sand making machines are equipped with an advanced transmission system that can increase the transmission efficiency.

Specifications

Configuration of 50ton/hour stone production line

| Equipment name | Model | Power (kw) | Qty (set) |

| Vibrating feeder | 850 ×3000 | 4.4 | 1 |

| Jaw crusher | 400 ×600 | 30 | 1 |

| Impact crusher | 1008 | 55 | 1 |

| Vibrating screen | 1235 | 5.5 | 1 |

| Conveyor | B500 | 3-4 | 6 |

Configuration of 200-250ton/hour stone production line

| Equip name | Model | Power (kw) | Qty (set) |

| Silo | / | / | 1 |

| Vibrating feeder | GZD1100 ×4200 | 4.4 | 1 |

| Jaw crusher | PE600 ×900 | 75 | 1 |

| Impact crusher | PF1214 | 160 | 1 |

| Vibrating screen | YK1854 | 22 | 1 |

| Conveyor | B500 ×15m | 4×3 | 3 |

| Conveyor belt | B800 ×20m | 5.5 | 1 |

| Conveyor belt | B1000 ×20m | 5.5 | 1 |

| Conveyor belt | B800 ×25m | 4 | 1 |

What Do Customers Talk About Us?

When stone crushing plants were delivered to Uganda, your engineers and workers came to our work site to help install them and explained to us how to operate them. What a pleasant collaboration!

– Anita Namugwanya

The construction waste crushing plant we bought from Shunzhi are highly efficient, we have an old series of plant but it didn’t work, after we use the plant from Shunzhi, we found they help saved large amount of operation costs!

– Juanita Nabankema

VSI Sand Making Machine VS. Mobile Sand Crusher

When it comes to making sand, two of the most commonly used methods are VSI and mobile sand making machine. Both have their advantages and disadvantages, but it’s important to weigh them carefully before making a decision.

VSI Crusher

VSI crushers are typically used for the crushing of hard, abrasive materials like gravel or granite. They are designed with a special rotor design that enables them to cut and shape the material into finer pieces. This makes them ideal for making high-quality sand with uniform particle sizes.

The downside to VSI crushers is that they require more power and generate more dust than mobile sand making machines.

Mobile Sand Making Machines

On the other hand, mobile sand making machines are designed to be used on-site and require less power compared to VSI crushers. They are also better for producing smaller sized particles which is ideal for making high-grade sand.

Additionally, mobile sand making machines are more environmentally friendly as they generate less dust and require fewer resources to operate.

The downside is it costs higher than VSI crusher based on its high mobility.

Which One Is Right For You?

Choosing between VSI crushers and mobile sand making machines can be a difficult decision. While both have their advantages, the size and type of materials you need to work with should be the biggest factor in deciding which option is right for you.

Consider how much power and dust your project requires, and whether mobility is an important factor. Once you have the answers to those questions, you can make a more informed decision.

Ultimately, it comes down to personal preference and which method suits your needs the best.

How to Choose the Right Crushing Methods for Sand Making?

When choosing the crushing methods for sand making, there are two main options – “rock on rock” and “rock on iron”.

The “rock on rock” method is ideal for crushing medium hard and hard materials with high abrasion resistance (granite, basalt and the like). The crushed material will have a more uniform shape and size, making it easier to process.

The “rock on iron” method is used for crushing materials that are softer or less abrasive. This method produces a more cubical shape in the final product and is often used for softer materials such as limestone, clay, and sandstone.

When choosing the right crushing method for your project, it’s important to consider the type of material you’re working with and the required shape and size of the finished product. If you need a more uniform shape and size, “rock on rock” is likely the best option for your needs. Conversely, if you need to achieve a more cubical shape, “rock on iron” is probably the best method.

No matter which crushing method you choose for your project, it’s important to ensure that the equipment you are using is of high quality and suitable for the job. Quality crusher machines will give you the best results and help you to avoid any costly mistakes.

Shunzhi Machinery provides high-quality and reliable crusher machines, designed to meet the needs of your project. With a wide selection of products and experienced professionals, we can help you find the perfect machine for your needs. Contact us today to learn more about our products and services.

Factors to Consider When Improving Sand Making Production Rate

1. Feeding Granularity: The size and hardness of the feed material has a great impact on the sand production rate of the sand making machine. Large-sized and harder materials are more difficult to crush, resulting in a lower production rate.

2. Feed Quantity: Too little feed will cause the sand making machine to work for a long time without stopping, resulting in high wear of the machine. Too much feed will cause the motor overload to reduce, resulting in a decrease in production rate.

3. Material Moisture Content: The amount of moisture in the feed material affects the sand production rate. A moist material is more difficult to crush and has a lower production rate.

4. Rotor Speed: The rotor speed of the sand making machine affects the production rate. If the speed is too high, it will cause uneven wear and tear of the wear parts, and if it is too low, the efficiency of material crushing will be reduced. The optimal rotor speed should be determined according to the material properties.

5. Air Volume of Separator: The air volume of the separator affects the sand production rate. Generally, a small air volume will cause the material to remain in the separator for too long, resulting in a decrease in production rate, and vice versa.

6. Standard Operation: The operator should be familiar with the operation flow of the sand making machine, and strictly follow the standard operating procedures to ensure that each system works properly.

7. Regular and Right Maintenance: Regular maintenance and repair of sand making machines can ensure their normal working condition and make them last longer, thus improving the production rate. In addition, replacement of worn parts is also required to achieve better production efficiency.

By adjusting these factors, the sand production rate of the sand making machine can be effectively improved. It is recommended that customers understand the material properties of their feed material and adjust the machine parameters accordingly to ensure maximum production efficiency.

How to Set up a High Profit Sand Making Plant?

Starting a sand making plant business is a great opportunity for entrepreneurs who want to make money in the construction industry. The business owner should focus on some factors before setting up your sand crushing plants.

Confirm Your Site Location

First, you need to make sure that your project site is suitable. You will also need to evaluate the local market and its needs for sand-making and other associated products. Additionally, you’ll need to consider the availability of raw materials and the processing capacity of the machinery.

Here are some tips to guide you to choose the best site for your sand crushing plants with the best price.

- Look for supply sources of raw materials: You need to identify the sources from where you can get the required raw materials. The distance of these sources to the site should be considered before making a final decision.

- Check on governmental regulations: Make sure you are aware of all local zoning and environmental regulations that may apply to your business.

- Evaluate the competition: You will need to research the market and find out what other sand-making plants are already present in the region. This can help you determine whether or not there is a viable market for your product.

- Check on the sources: Ensure your selected worksite is abundant in water resources, has access to electricity, and is convenient in traffic.

- Consider your business scale: You should consider the size of your business, that is, whether you are setting up a small-scale sand crushing plant or a large-scale operation.

Purchase Machinery

Once you have identified a suitable location for your project, the next stage is to purchase the required machinery. The most important aspect here is cost-effectiveness. You should buy machinery that is energy efficient, reliable, and produces a high quality output in the required quantity. Make sure to thoroughly research each option and compare prices before making your purchase.

To invest in a profitable sand crushing business, you should configure must-have machines like vibrating feeder, crusher machines, sand making machines, screener, sand washer, etc.

Some auxiliary machines like roller crushers, conveyor belts, silos, sand recliamer, etc.

Recruit Skilled Professionals

You will need to hire professionals with expertise in operating the sand-making plant. It is important to invest in recruiting qualified and experienced personnel who can handle the plant operations efficiently. You should also brief them on the expected output and ensure that they understand how to follow safety protocols.

Develop Effective Marketing Strategies

Once you have put together a team and acquired the necessary machinery and resources, it is time to think of a marketing strategy. You should develop an effective plan that will help you reach out to your target audience and communicate the advantages of using sand-making plants.

Finalize Your Business Plan

Finally, you should create a business plan that outlines the objectives and goals of your business. This should include a detailed budget, a market analysis, and feasibility study. The plan should also include information about the resources and personnel required to set up and operate the plant.

Starting a sand-making plant business requires careful research, planning, and execution. It is important to take into consideration the various factors mentioned above in order to ensure success. With the right resources and a solid business plan, you can set up a high-profit sand-making plant business.

Shunzhi has been in the crushing and screening manufacturing machines for over 30 years, and we specialize in producing jaw crusher, impact crusher, cone crusher, sand making machine, rock and stone crushing equipment and vibrating screen. We also offer tailoring services to meet your individual needs. Therefore, if you’re interested in setting up a sand-making plant business, get in touch with us today for more information.